2018 Latest Design Plain Pp Gusseted Bags 50kg - Block Bottom Valve PP Woven Rice Bag – Jintang

2018 Latest Design Plain Pp Gusseted Bags 50kg - Block Bottom Valve PP Woven Rice Bag – Jintang Detail:

Model No.:Boda-ad

Application:Food, Chemical

Feature:Moisture Proof, Recyclable, Antistatic

Material:PP

Shape:Square Bottom Bag

Making Process:Composite Packaging Bag

Raw Materials:Polypropylene Plastic Bag

Bag Variety:Your Bag

Woven Fabric:100% Virgin PP

Laminating:PE

Bopp Film:Glossy Or Matte

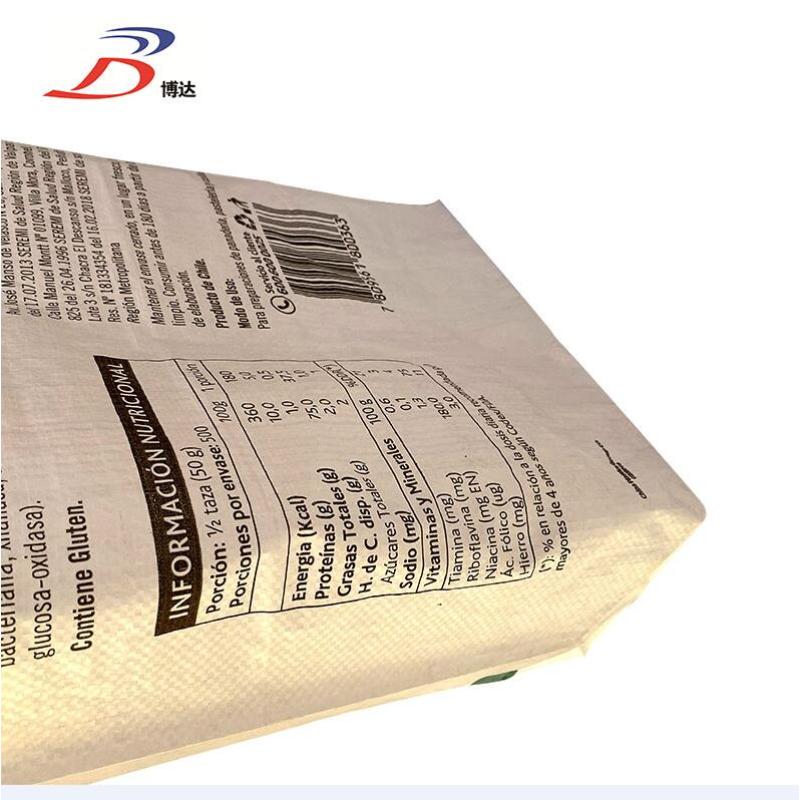

Print:Gravure Print

Gusset:Available

Top:Easy Open

Bottom:Stitched

Surface Treatment:Anti-slip

UV Stabilization:Available

Handle:Available

Additional Info

Packaging:Bale/ Pallet/ Export carton

Productivity:3000,000pcs per month

Brand:Boda

Transportation:Ocean,Land,Air

Place of Origin:China

Supply Ability:on time delivery

Certificate:ISO9001, SGS, FDA, RoHS

HS Code:6305330090

Port:Tianjin,Qingdao,Shanghai

Product Description

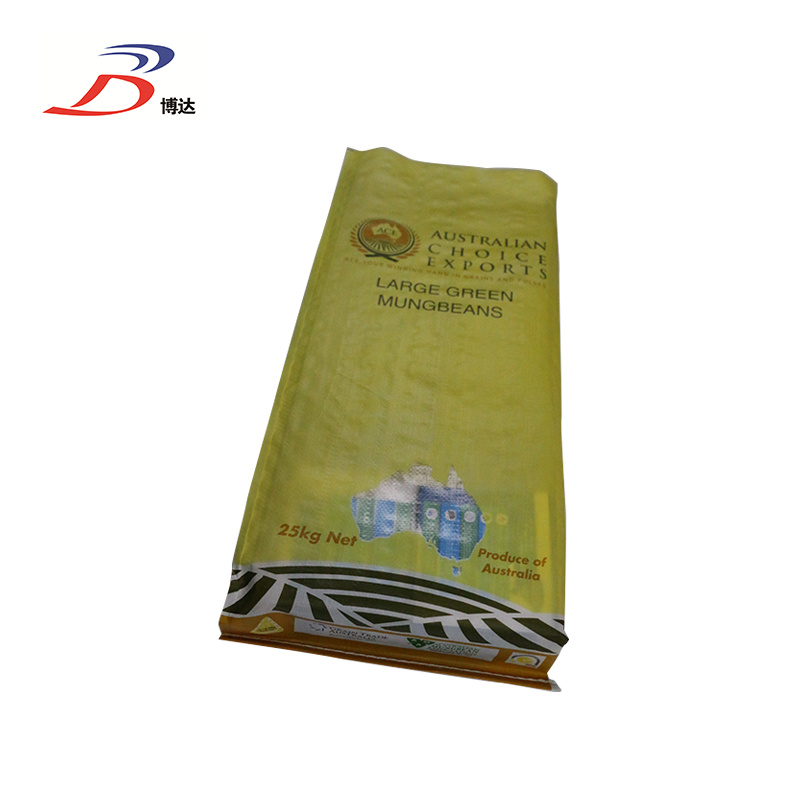

Rice bags are requested to be insect-resistant, mildew-proof and well-preserved. And to win the competition in the market, Rice bags need to be in aesthetic appearance for brand promotion. Pp Woven Bags perfectly offers the features which could meet above requests.

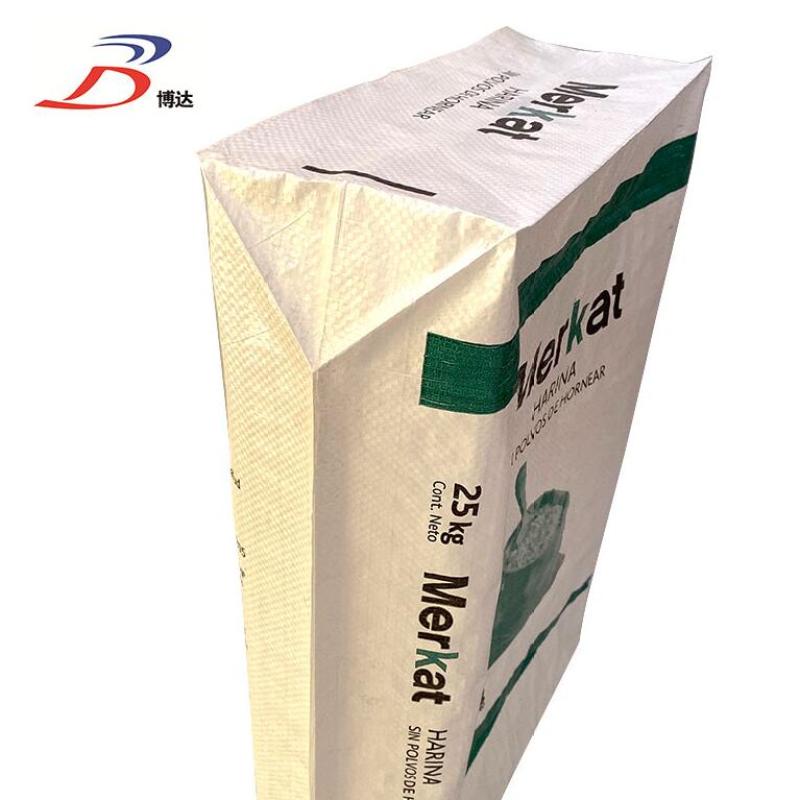

Here we would like to say some more about Block Bottom Valve Bags: made of 100% PP, hot welded bottom and auto-filling mouth. No glue, no stitching, no hole. More functional and more healthy and safe.

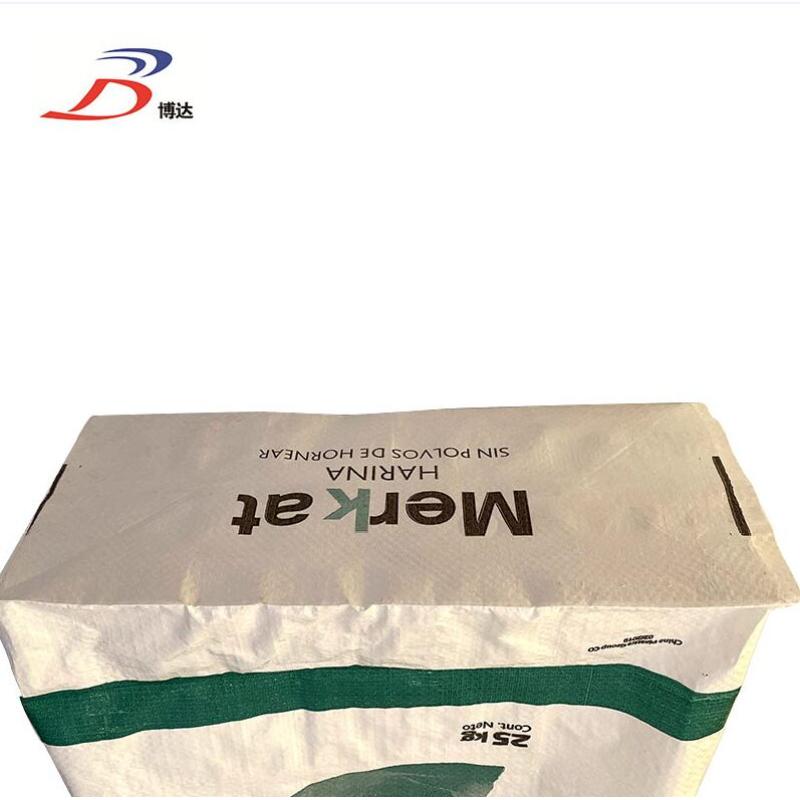

Block Bottom bags take a box-type shape after filling thus offers more printing surfaces on the bag through Top & Bottom Flat which can be read from sides when the bags are stacked. This increases visibility for the customers and adds to the brand image and better market value.

High humidity and rough handling is easily tolerated by Block Bottom bags. So they arrive without any broken at customer warehouse, resulting in utmost customer satisfaction.

Produce with European technology, Block Bottom Valve Bag is a superior type of product in comparison with traditional packaging products with prominent features as follows:

- High strength, no breakage and spillage of goods

- Micro perforation with good air permeability

- Better printing quality and design

- Gentle dimension, storage space saving

- Competitive cost

AD*STAR® is the well-known sack concept for powdery material – in use worldwide, patented internationally, and produced exclusively on Starlinger machines. The brick-shaped PP woven sacks, produced without adhesives by heat-welding of the coating on the fabrics, was developed with automated filling and landing processes in mind. As a result of the material characteristics and the special production process, the weight of an average 50 kg AD*STAR® rice sack can be as low as 75 grams. A comparable 3-layer paper bag will weigh about 180 grams and PE-film bag 150 grams. An economical use of raw material not only helps minimize cost, it is also a valuable contribution to the preservation of our environment.

Fabric Construction – Circular Pp Woven Fabric (no seams) or Flat PP Woven Fabric (back seam bags) Laminate Construction – PE coating or BOPP Film Fabric Colors – White, Clear, Beige, Blue, Green, Red, Yellow or customized Printing – Off-set print, Flexo print, gravure print. UV Stabilization – Available Packing – 5,000 Bags per Pallet Standard Features – No stitching, completely hot welding

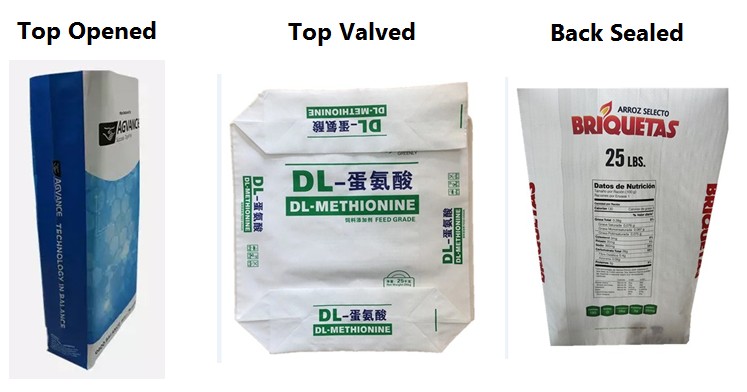

Optional Features:

Printing Anti-slip Embossing Micropore

Valve extendable Kraft paper combinable Top opened or valved

Sizes Range:

Width: 350mm to 600mm

Length: 410mm to 910mm

Block width: 80-180mm

Weave: 6×6, 8×8, 10×10, 12×12, 14×14

Our company

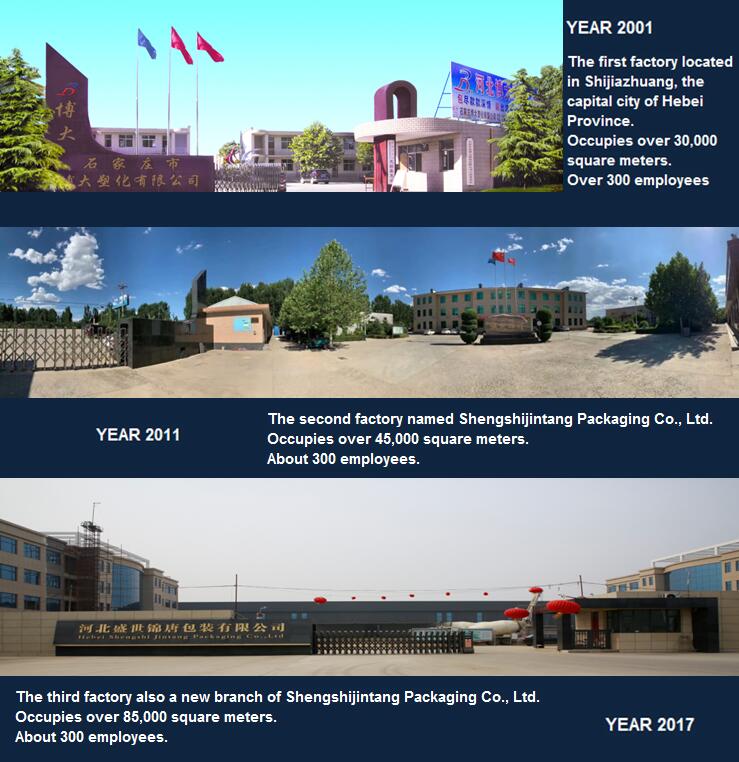

Boda is one of China’s top packaging producers of specialty Polypropylene Woven Bags. With world-leading quality as our benchmark, our 100% virgin raw material, top-grade equipment, advanced management, and dedicated team allow us to supply superior bags all over the world.

Our company covers an area totally of 160,000 square meters and there are more than 900 employees. We possess a series of advanced Starlinger equipment including extruding, weaving, coating, laminating and bag produce. What’s more, we are the first manufacturer in domestic that imports the AD* STAR equipment in the year 2009 for Block bottom valve bag Production.

Certification: ISO9001, SGS, FDA, RoHS

Our main products are: PP woven bags, BOPP Laminated Woven Sacks, BOPP Back seam bag, PP Big Bag , PP woven fabric

Looking for ideal Block Bottom Rice Bag Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Customized PP Woven Rice Sack are quality guaranteed. We are China Origin Factory of Laminated Poly Woven Rice Bag. If you have any question, please feel free to contact us.

Product Categories : PP Woven Bag > PP Woven Agricultural Bag

Product detail pictures:

Related Product Guide:

Troubleshooting during the production of woven bags

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for 2018 Latest Design Plain Pp Gusseted Bags 50kg - Block Bottom Valve PP Woven Rice Bag – Jintang , The product will supply to all over the world, such as: Mauritius, Korea, Italy, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.