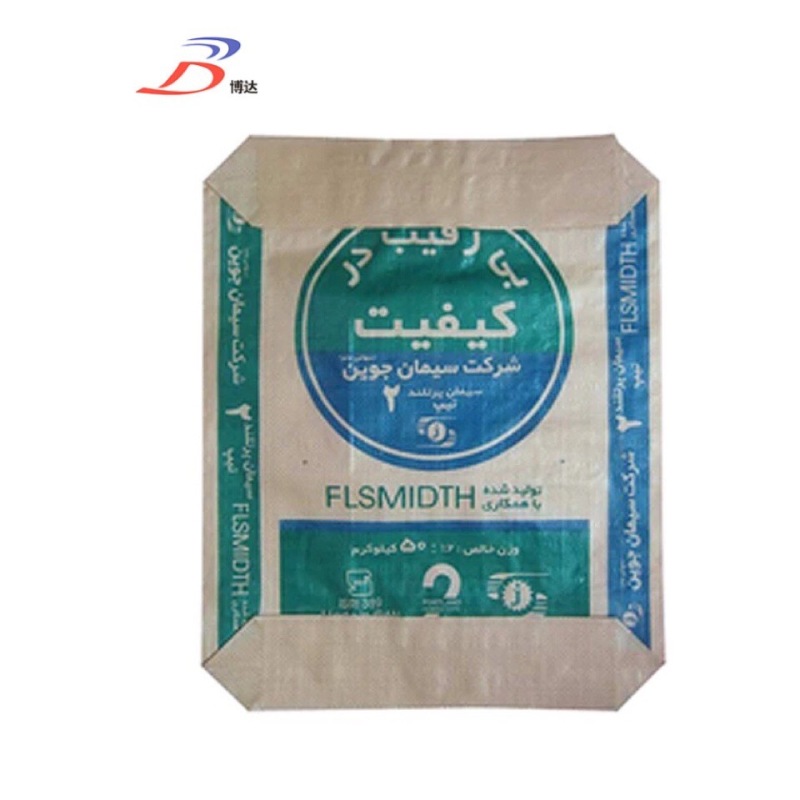

25kg extended valve bag

1.PRODUCT DESCRIPTION:

A new tecknology on packaging , without any adhesives or stitching, just through hot air welding, the tubular woven fabric can become a finished bag within several minutes.

The step of the hot sealed bags processing begins from a coated pp woven fabric, and then, cutting, folding the bottom, welding with layers, bag finishing, totally by one machine, AD* STARKON.

block bottom valve bags is commonly used for the automatic packaging, transportation, and storage of cement, fertilizer, granulates, animal feed, and many other dry bulk products. The bag is stronger than paper, quick to

fill, and has a good moisture barrier; all qualities that have contributed to the sharp increase in the use of this packaging type.

plastic valve bags loading is from 25 to 50kg, and printing can be offset, flexo, and also gravure print.

pp woven valve bag are perforated with a star micro-perforation system which allows air to come out holding the cement or other material without allowing any seepage.

Compared to other industrial sacks, adstar bags are strongest bags in polypropylene woven fabric. That make it resistant to dropping, pressing, puncturing and bending.

Worldwide cement, fertilizers and other industries have observed a zero breakage rate, doing all stages, the filling, the storage, the loading and the transportation.

☞Bag Made from coated PP woven fabric, with outside PE lamination for moisture resistance.

☞Top with valve for automatic closure.

☞Specifications and printing could be according to the customer's requests

☞Eco-friendly polypropylene material can be fully recyclable

vEconomical use of raw material than a 3-layer paper bag and PE-film bag

☞Impressive reduction of the breakage rate when compared with conventionally used paper sacks

☞Suitable for packing all types of free-flowing goods, such as cement, building materials, fertilizer, chemicals, or resin as well as flour, sugar, or animal feed.

2.BAG PARAMETER:

Name

|

Ad Star block bottom valve bags

|

Raw Materials

|

100% New polypropylene PP granules

|

SWL

|

10kg-100kg

|

Raffia Fabric

|

white, yellow, green, transparent, fabric color as customized

|

Moistureproof

|

Laminated PE or PP, inside or outside (14gsm-30gsm)

|

Inside liner

|

Kraft paper laminated inner or not

|

Printing

|

A. Offset printing (Up to 4 colors)

B. Flexible printing (Up to 4 colors)

C. Gravure printing(Up to 8 colors, OPP film or matte film could be choosen)

D. one side or both sides

E. non-slip adhesive

|

Width

|

More than 30cm, less than 80cm

|

Length

|

From 30cm to 95cm

|

Denier

|

450D to 2000D

|

Weight/m²

|

55gsm to 110gsm

|

Surface

|

glossy/matt lamination, anti-UV coating, antiskid, breathable, Anti-slip or flat plain etc..

|

Bag Top

|

Cut, circular welding hemmed, with filling valve

|

Bag Bottom

|

Hot air welding, no sewing, no stitching hole

|

Liner

|

Kraft paper inside , inner attachment or welding plastic PE plastic bag , customized

|

Bag type

|

Tubular bag or back middle seamed bags

|

Packing term

|

A. Bales (free)

B. Pallets (25$/pc) : about 4500-6000 pcs bags /pallet

C. Paper or wooden cases (40$/pc) : as true situation

|

Delivery Time

|

20-30 days after receiving deposit or L/C original

|

3.QUALITY CONTROL:

4.COMPANY INTRODUCE:

Shijiazhuang Boda Plastic Chemical Co., Ltd, is a pp woven bag manufacturer engaged in this industry since 2003.

With the continuous increasing demand and a great passion for this industry,

we now have a wholly-owned subsidiary named Shengshijintang Packaging Co., Ltd.

We occupy a total of 16,000 square meters of land, around 500 employees working together.

We possess a series of advanced Starlinger equipment including extruding, weaving, coating, laminating, and bag produce.

It was worth mentioning that, we are the first manufacturer in domestic that imports the AD* STAR equipment in the year 2009.

With the support of 8 sets of ad starKON , our annual out put for AD Star bag exceeds 300 million.

Besides the AD Star bags, BOPP bags, Jumbo bags, as traditional packaging options, are also in our main product lines.

5.PACKAGING DETALS:

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags