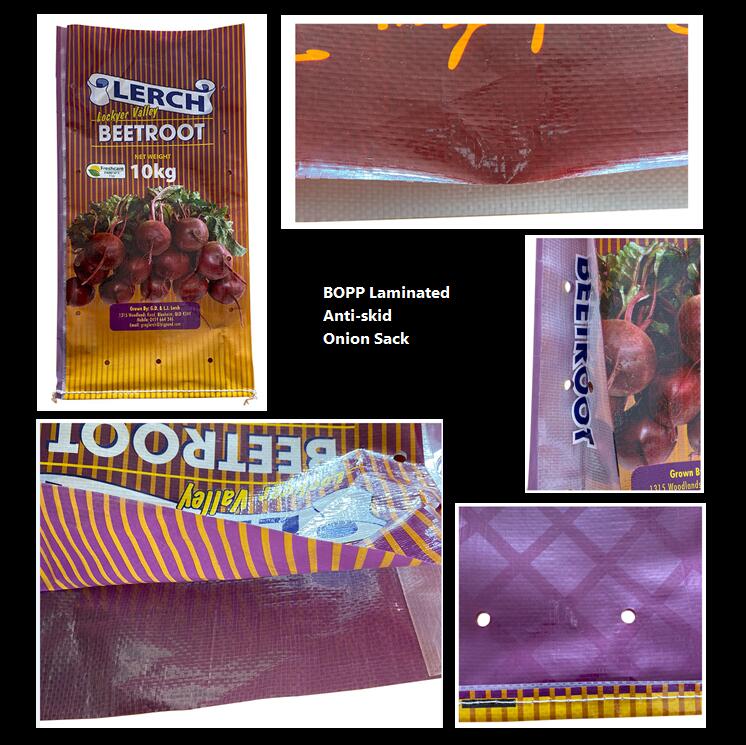

China Manufacturer for China Polypropylene Sacks - 10kg Printed BOPP laminated onion jute bag – Jintang

China Manufacturer for China Polypropylene Sacks - 10kg Printed BOPP laminated onion jute bag – Jintang Detail:

Model No.:Boda-opp

Woven Fabric:100% Virgin PP

Laminating:PE

Bopp Film:Glossy Or Matte

Print:Gravure Print

Gusset:Available

Top:Easy Open

Bottom:Stitched

Surface Treatment:Anti-slip

UV Stabilization:Available

Handle:Available

Application:Food

Feature:Moisture Proof, Recyclable

Material:BOPP

Shape:Plastic Bags

Making Process:Plastic Packaging Bags

Raw Materials:Polypropylene Plastic Bag

Bag Variety:Your Bag

Additional Info

Packaging:Bale/ Pallet/ Export carton

Productivity:3000,000pcs per month

Brand:Boda

Transportation:Ocean,Land,Air

Place of Origin:China

Supply Ability:on time delivery

Certificate:ISO9001, BRC, Labordata, RoHS

HS Code:6305330090

Port:Tianjin,Qingdao,Shanghai

Product Description

BOPP laminated Pp Woven Bags, Biaxially Oriented Polypropylene (BOPP) Film is produced by stretching a polypropylene cast film both in the length and width directions.

Advantages:

1. High tensile strength that facilitates high-speed conversion

2. Good puncture and flex-crack resistance over a wide range of temperatures

3. Slip resistant properties

4. Resistant to oils and greases

5. Does not wrinkle or shrink with environmental changes

6. Premium print quality

7. Retail quality appearance

8. High gloss or matte finishes with clarity

9. Good barrier to water vapor

Why to choose Boda for BOPP Laminated Bag

Our AD*Star equipment have higher requirement of the raw material, specially for the BOPP laminated woven Bag are made from high-end PP material to ensure best quality printing as well as highly reliable packaging and storage solutions. We are the first factory in demostic that import Starlinger equipment for block bottom bag production.

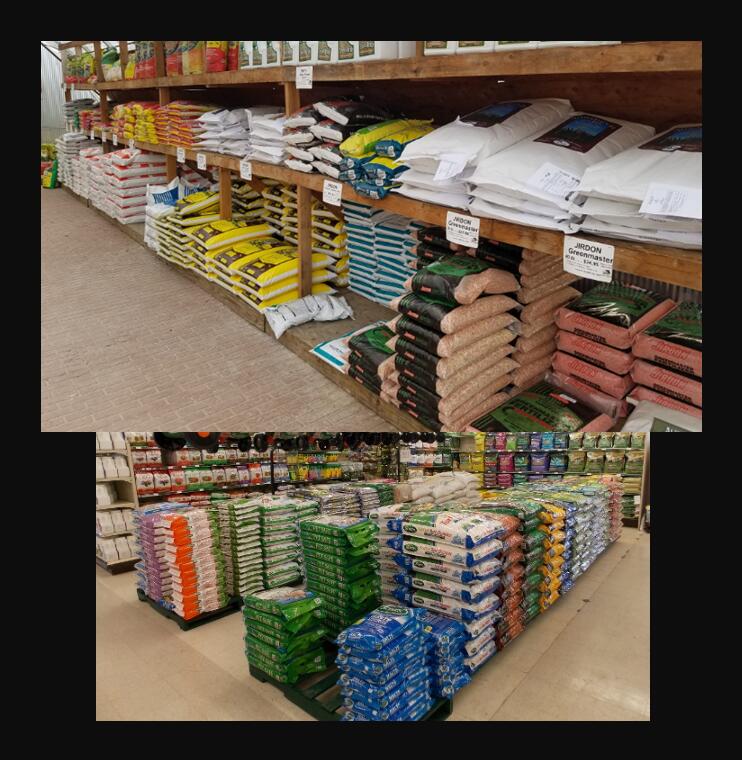

PP woven bag, PP Vegetable Bag exported from our company get highly comments due to they well promoted our client’s reputation.

Laminated Woven Bag Specifications:

Fabric Construction: Circular Pp Woven Fabric (no seams) or Flat WPP fabric (back seam bags)

Laminate Construction: BOPP Film, glossy or matte

Fabric Colors: White, Clear, Beige, Blue, Green, Red, Yellow or customized

Laminate Printing: Clear film printed using 8 Color technology, gravure print

UV Stabilization: Available

Packing: From 500 to 1,000 Bags per Bale

Standard Features: Hemmed Bottom, Heat Cut Top

Optional Features:

Printing Easy Open Top Polyethylene Liner

Anti-slip Cool Cut Top Ventilation Holes

Handles Micropore False Bottom Gusset

Sizes Range:

Width: 300mm to 700mm

Length: 300mm to 1200mm

Looking for ideal Printed PP Woven Sack Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the BOPP Oinon PP Bag Packaging are quality guaranteed. We are China Origin Factory of Laminated Woven Sack For Onion. If you have any question, please feel free to contact us.

Product Categories : PP Woven Bag > PP Vegetable Bag

Product detail pictures:

Related Product Guide:

Troubleshooting during the production of woven bags

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for China Manufacturer for China Polypropylene Sacks - 10kg Printed BOPP laminated onion jute bag – Jintang , The product will supply to all over the world, such as: Karachi, Angola, Mozambique, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!