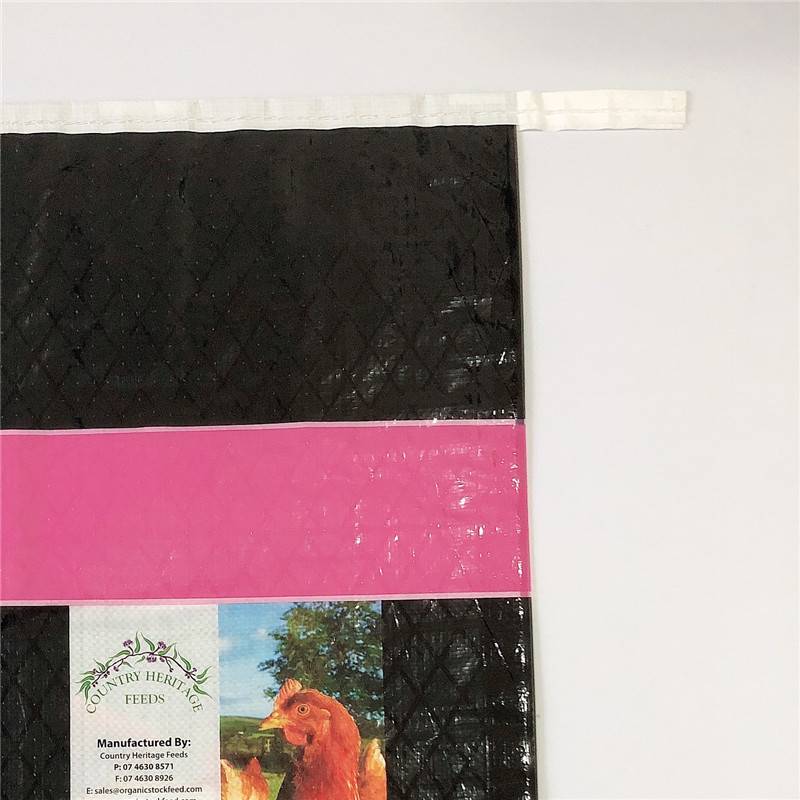

Bopp Laminated Stock Feed Bag

DESCRIPTION:

POLYPROPYLENE (PP) WOVEN BAGS

BODA(JINTANG PACKAGING) is a leading company in manufacturing fabrics and pp woven bags and polypropylene packaging of recognized national and international prestige, especially here in Asia, where it stands out because of the variety and quality of its product line.

our company supplies national and foreign markets in Russia, the Philippines, Singapore, Korea, Romania, Belgium, Netherlands, Spain, etc. These demanding markets force us to work with the highest possible quality and productivity standards.

Interweaving polypropylene tapes produce woven PP (polypropylene) bags in two directions; they are known for their strength and durability. They are tough, breathable, cost-effective bags ideally suited for packaging agricultural products like grains, pulses, seeds, and sugar and products diverse as sand, fodder, chemicals, cement, metal parts, etc.

We are pleased to offer various options to suit the application best. PP woven bags with coating and liners are ideal for packaging products at risk of leaking, from fine granules like sugar or flour to more hazardous materials like fertilizers or chemicals. Liners help protect the integrity of your product by avoiding contamination from outside sources and reducing the release or absorption of humidity.

Whether you have a proven design or would like a professional’s assistance or opinion, please contact us today. We look forward to discussing your needs and finding the perfect fit.

| No. | Item | Specification |

| 1 | Shape | Tubular or Back Seam |

| 2 | Length | 300mm to 1200mm |

| 3 | Width | 300mm to 700mm |

| 4 | Top | open, or Hot Air Welded with Filling Valve |

| 5 | Bottom | sewing, or Hot Air Welded no Stitching, No Hole |

| 6 | Printing type | Offset or Gravure printing on one or two side, up to 8colors |

| 7 | Mesh size | 8*8, 10*10, 12*12, 14*14 |

| 8 | Bag weight | 50g to 150g |

| 9 | Air permeability | 20 to 160 |

| 10 | Color | white, yellow, blue or customized |

| 11 | Fabric weight | 58g/m² to 220g/m² |

| 12 | Fabric treatment | anti-slip or laminated or plain |

| 13 | PE lamination | 14g/m² to 30g/m² |

| 14 | Application | For packing the cement, stock feed, animal feed, pet food, chemical, flour, rice, putty powder etc. |

| 15 | Inside liner | With PE liner or not;Can be combined with kraft paper and into a two layers bag |

| 16 | Characteristics | auto-filling, self-filling, easy for pallet pack, save warehouse space, misture-proof, tightness, highly tensile, tear resistant, eco-friendly ink |

| 17 | Meterial | 100% original Polypropylene |

| 18 | Optional choice | Inner laminated, side gusset, back seamed, combined with kraft paper. |

| 19 | Package | about 500pcs for one bale or 5000pcs one wooden pallet |

| 20 | Delivery Time | within 25-30days for one 40H container |

Advantages/Characteristics of PP Woven Bags,BOPP laminated stock feed bag

- Tear resistant, reducing costly losses of products and reworking costs

- Custom two-sided printing is available

- Can be custom-designed to meet client specifications

- Available with flat or anti-slip weaving

- Available with or without liner

- Bags may be heat cut, cold cut, or hemmed top

- Can be laminated or non-laminated

- It can be gusseted or pillow/tube

- Available in any color or transparent

- Widely used for products needing to breathe (preventing mold or decomposition)

Packaging:

Bale packing: 500,1000pcs/bale or customized. Free of charge.

Wooden Pallet packing: 5000pcs per pallet.

Export carton packing: 5000pcs per carton.

Loading:

1. For 20ft container, will load about:10-12tons.

2. For a 40HQ container, will load about 22-24tons.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags