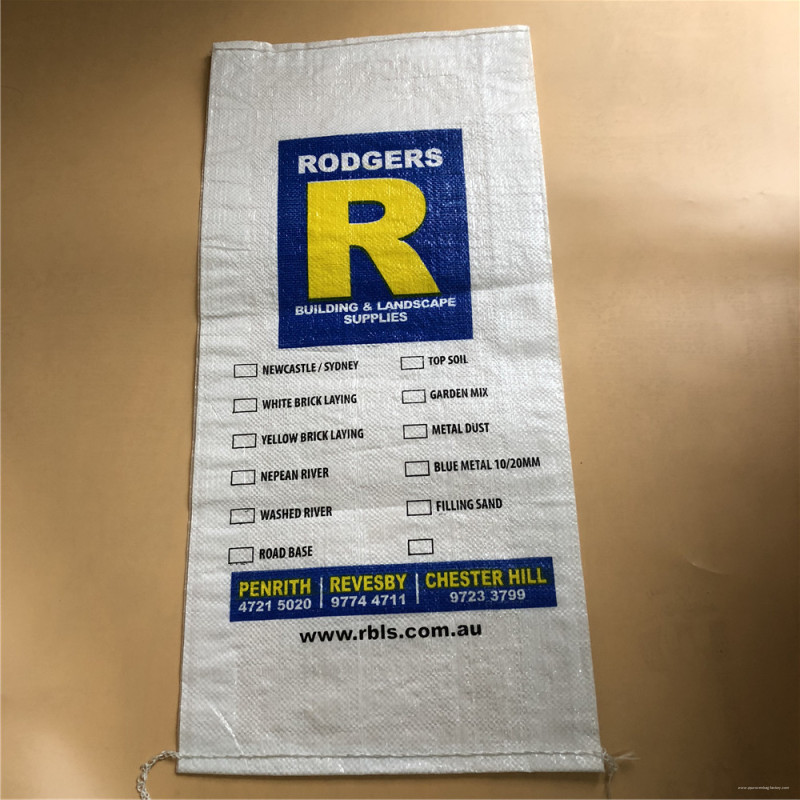

factory Outlets for Polypropylene Gusseted Bag - feed sacks for sale – Jintang

factory Outlets for Polypropylene Gusseted Bag - feed sacks for sale – Jintang Detail:

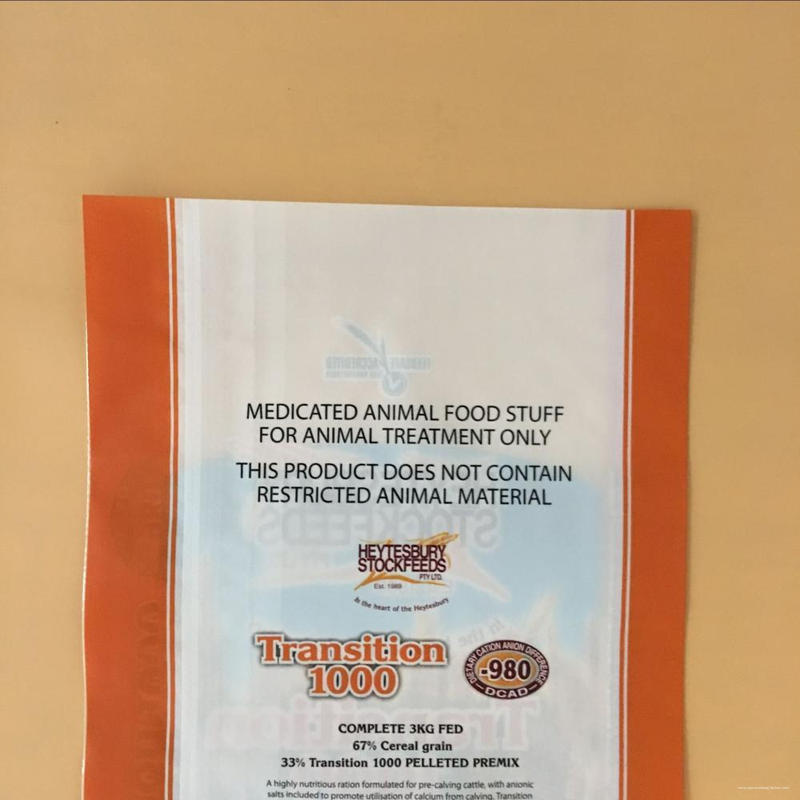

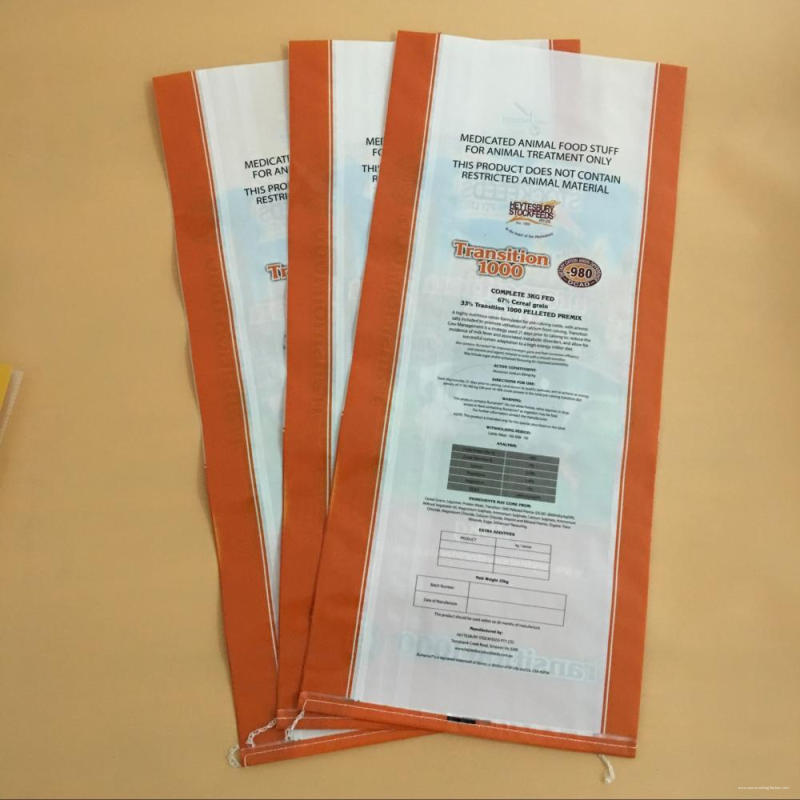

Model No.:Back seam laminated bag-004

Application:Promotion

Feature:Moisture Proof

Material:PP

Shape:Plastic Bags

Making Process:Plastic Packaging Bags

Raw Materials:Polypropylene Plastic Bag

Additional Info

Packaging:500PCS/Bales

Productivity:2500,000 per week

Brand:boda

Transportation:Ocean,Land,Air

Place of Origin:china

Supply Ability:3000,000PCS/week

Certificate:BRC,FDA,ROHS,ISO9001:2008

HS Code:6305330090

Port:Xingang Port

Product Description

Shijiazhuang boda plastci chemical co.,ltd is one of the well-known manufacturer, exporter and domestic supplier of HDPE / PP Woven Fabrics, HDPE / PP Woven Sacks / Bags and Multicolor Printed BOPP Laminated PP Woven Sacks and Bags for the last many years. We are well-known for co-creating innovative, reliable and high quality solutions for the plastic industry.

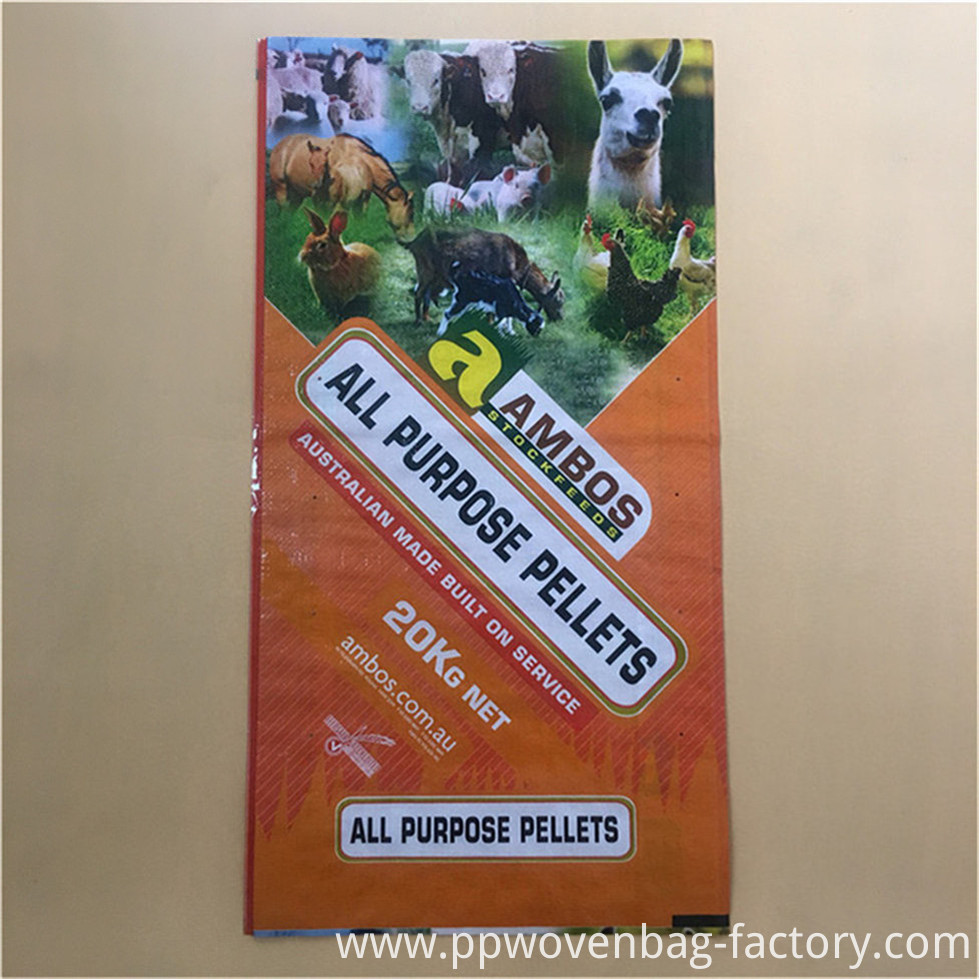

These BOPP printed woven feed bags are manufactured according to the international quality standards and

these hugely used in different industrial and commercial applications with the guarantee of longer shelf life of stored items which are perishable and non-perishable.

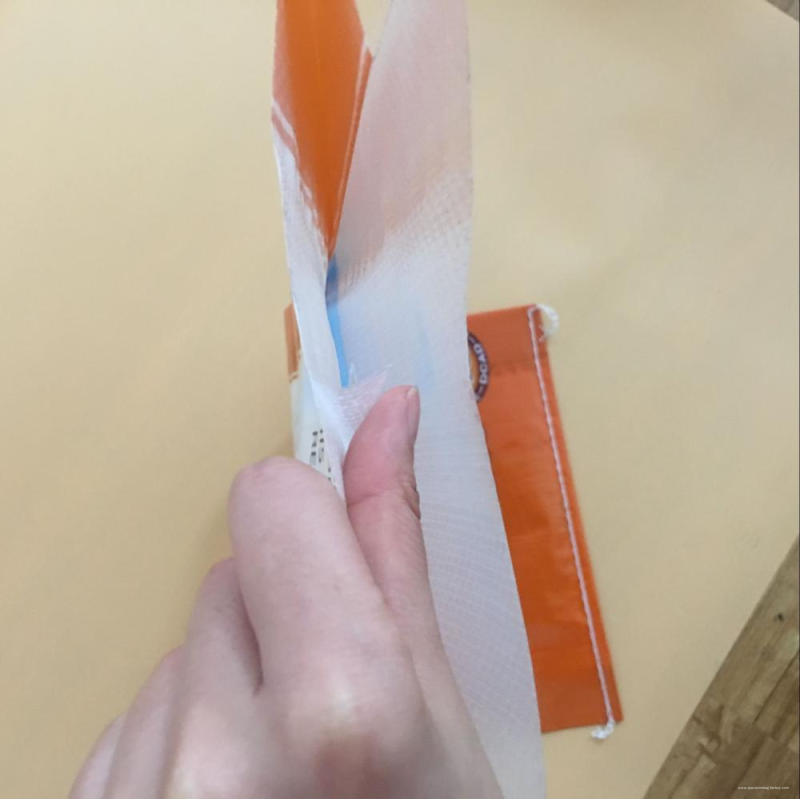

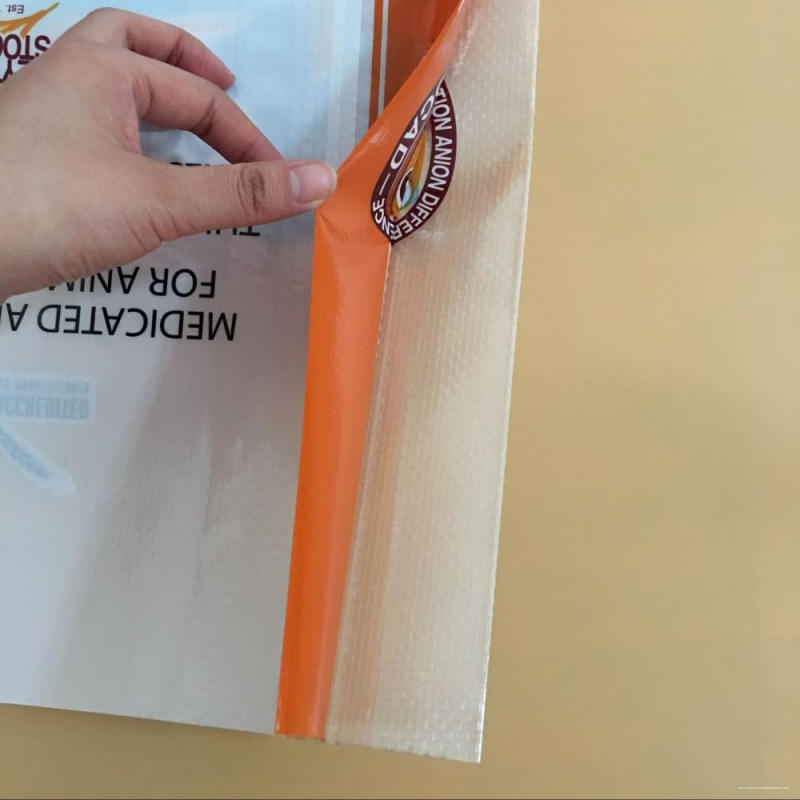

Item Back Seam Laminated Bag Material composition Virgin PP Thickness 60-100gsm Of Woven Polypropylene Width 30cm-100cm Length Customized Capacity 5kgs-100kgs Top Heat-cut/Cold cut /Hemmed Bottom Stitched/Hot melt sealed. Printing Gravure printing. Up to 7C. Mesh 10×10 Plate charge 100USD/Color each side. MOQ 50,000PCS Lead time 30 – 45days Moisture HDPE/LDPE Liner Packing 500PCS/Bale, Or as customized. Application For animal feed packing. Payment terms 1. TT 30% down payment. Balance against B/L copy. 2. 100% LC At sight. 3. TT 30% down payment, 70% LC At sight.

Looking for ideal Feed Sacks for Sale Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Pp Feed Sack are quality guaranteed. We are China Origin Factory of Feed Sack Bags. If you have any question, please feel free to contact us.

Product Categories : PP Woven Bag > Back Seam Laminated Bag

Product detail pictures:

Related Product Guide:

Troubleshooting during the production of woven bags

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for factory Outlets for Polypropylene Gusseted Bag - feed sacks for sale – Jintang , The product will supply to all over the world, such as: Afghanistan, Swedish, Seattle, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.