Factory Price Block Bottom Valve Putty Packaging Bag - Industrial customized PP back seam sand sack – Jintang

Factory Price Block Bottom Valve Putty Packaging Bag - Industrial customized PP back seam sand sack – Jintang Detail:

Model No.:Boda-opp

Application:Chemical

Feature:Moisture Proof

Material:PP

Shape:Plastic Bags

Making Process:Composite Packaging Bag

Raw Materials:Polypropylene Plastic Bag

Bag Variety:Upright Bag

Woven Fabric:100% Virgin PP

Laminating:PE

Bopp Film:Glossy Or Matte

Print:Gravure Print

Gusset:Available

Top:Easy Open

Bottom:Stitched

Surface Treatment:Anti-slip

UV Stabilization:Available

Handle:Available

Additional Info

Packaging:Bale/ Pallet/ Export carton

Productivity:3000,000pcs per month

Brand:Boda

Transportation:Ocean,Land,Air

Place of Origin:China

Supply Ability:on time delivery

Certificate:ISO9001, SGS, FDA, RoHS

HS Code:6305330090

Port:Tianjin,Qingdao,Shanghai

Product Description

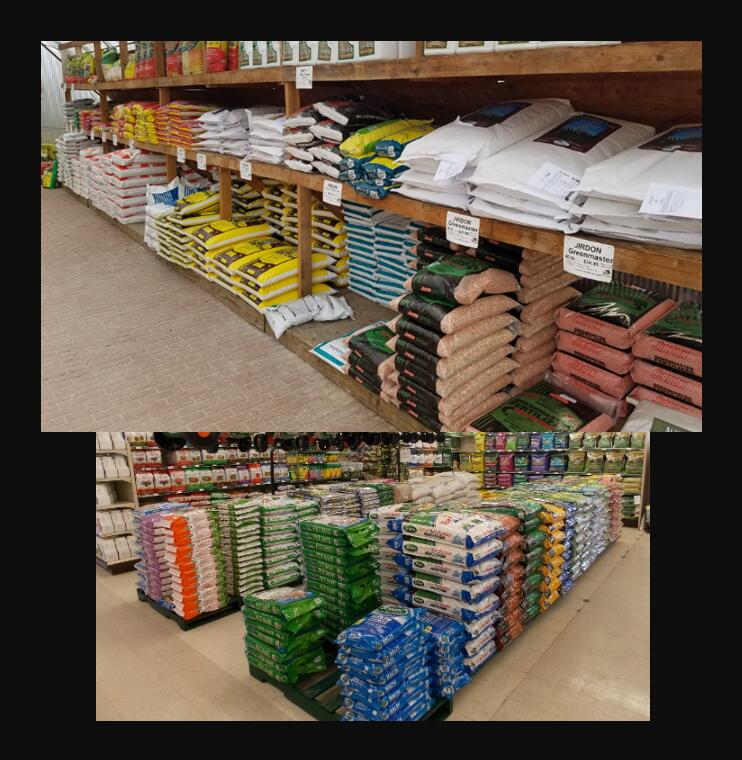

If you’re looking for retail ready packaging, that’s eco-friendly, strong, light and eye-catching BOPP bags could be just the ticket.

BOPP Laminated Pp Woven Bags offer excellent clarity and are completely waterproof. These are made from special materials that offer lowest electrostatic charge, if any. These bags are more attractive with multicolor printing on both sides. As laminated and printed from both sides the product gets good protection and bag gets good strength.

In either high-gloss, matt-finish, metalised or pearlised finishes. They can be produced with or without UV stabilisation.

Product Specifications:

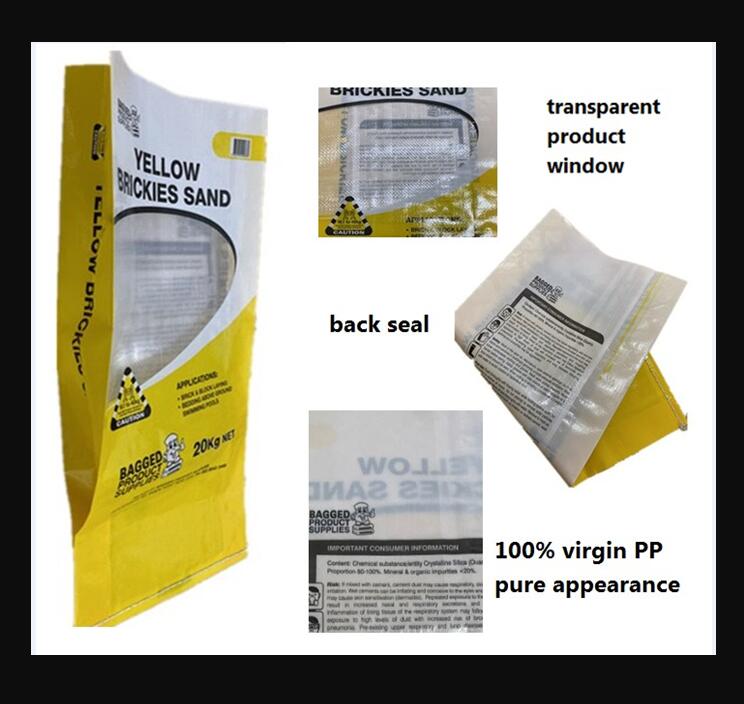

Fabric Construction: Circular Pp Woven Fabric (no seams) or Flat WPP fabric (back seam bags)

Laminate Construction: BOPP Film, glossy or matte

Fabric Colors: White, Clear, Beige, Blue, Green, Red, Yellow or customized

Laminate Printing: Clear film printed using 8 Color technology, gravure print

UV Stabilization: Available

Packing: From 500 to 1,000 Bags per Bale

Standard Features: Hemmed Bottom, Heat Cut Top

Optional Features:

Printing Easy Open Top Polyethylene Liner

Anti-slip Cool Cut Top Ventilation Holes

Handles Micropore False Bottom Gusset

Sizes Range:

Width: 300mm to 700mm

Length: 300mm to 1200mm

How to produce a BOPP bag

BOPP bag has different layers in the bag and they are also known as Multi layer bag, HDPE/PP Woven Fabric is one of the layer in the bag, Firstly we prepare a multi colored BOPP films through engraved cylinders and Rotogravures reverse printing technology. Then it is laminated with HDPE/PP Woven Fabrics and finally the cutting and stitching is done as per the requirements.

The printing process is done through engraved cylinders and Rotogravures reverse printing technology, up to 8 colors can be printed on the single Bag , we have got a graphic department , they develop various customized designs for the particular product with the specific images and back ground colors etc , once the designs are finalized the cylinders are engraved to print the same.

Application:

1. Pet food 2. Stock feed 3. Animal Nutrition4. Grass seed 5. Grain/Rice6. Fertilizer 7. Chemical 8. Building material 9. Minerals

Our company

Boda is one of China’s top packaging producers of specialty Polypropylene Woven Bags. With world-leading quality as our benchmark, our 100% virgin raw material, top-grade equipment, advanced management, and dedicated team allow us to supply superior bags all over the world.

Our company covers an area totally of 160,000 square meters and there are more than 900 employees. We possess a series of advanced Starlinger equipment including extruding, weaving, coating, laminating and bag produce. What’s more, we are the first manufacturer in domestic that imports the AD* STAR equipment in the year 2009 for Block Bottom Valve Bag Production.

Certification: ISO9001, SGS, FDA, RoHS

Looking for ideal Customized PP woven bag Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the BOPP Back Seam Sand Bag are quality guaranteed. We are China Origin Factory of Printed Sand PP Woven Sack. If you have any question, please feel free to contact us.

Product Categories : PP Woven Bag > Industrial PP Woven Sack

Product detail pictures:

Related Product Guide:

Troubleshooting during the production of woven bags

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Factory Price Block Bottom Valve Putty Packaging Bag - Industrial customized PP back seam sand sack – Jintang , The product will supply to all over the world, such as: Singapore, Croatia, Indonesia, With more than 9 years of experience and a professional team, we have exported our products to many countries and regions all over the world. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.