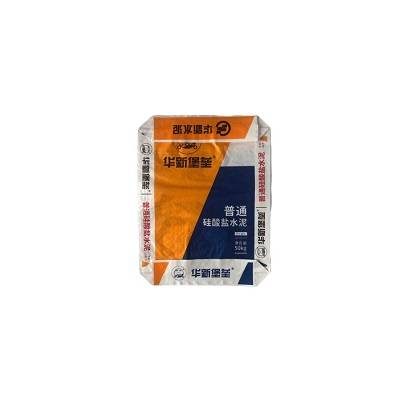

Bag ciminti 50kg

Tsarin mai amfani ya shafi jakar ciminti wanda aka kafa daga filastik, wanda Layer ya sa siliki na tsakiya wanda aka sanya wa robobi na Polypropylene. Daga cikin waɗannan, ana ɗaukar Polypropylene a matsayin mafi mahimmancin wani muhimmin abu na ciyawar jaka masana'anta masana'antu kuma yana shafar ingancin mai amfani. Bari mu gano kayan ciminti na ciminti da kuma cikakkiyar tsarin cirewa na masana'antu

PP yarn -> Waya Pup Mahalli

Ana samar da layin samarwa da ciminti a ƙarƙashin tsari mai rikitarwa.

1.Sanya pp yarn

PP filastik Granules an ɗora su cikin homan na'urar Yarn-form na kirkirar yarn, ta hanyar mashin din din din din din din din din din din din din din ya narke. A takaice dunƙule na filastik zuwa bakin teku mai daidaita da kuma daidaitacce da kauri, da fim ɗin filastik an kafa ta hanyar samar da ruwa mai wanka. Sannan fim din ya shiga shinge mai cutarwa don tsinkaye a cikin faɗin da ake buƙata (2-3 mm), yarn yana tafiya ta hanyar mai shayarwa don sanya injin iska.

A kan aiwatar da samar da yarn, fiber na fiber na fim ana iya dawo da shi ta hanyar tsotsa, a yanka a kananan guda, kuma ya koma zuwa ga wuta, kuma ya koma zuwa ga wuta, kuma ya koma zuwa ga wuta, kuma ya koma zuwa ga wuta, kuma ya koma zuwa ga wuta, kuma ya koma zuwa ga wuta, kuma ya koma zuwa ga wuta, kuma ya koma zuwa ga kafaffen.

2.Siffar PP Fabrairu

Ana sanya rolls na pp yarn a cikin madaukakin murhun ruwa na 06 don saƙa cikin bututun Pp na Pp, ta hanyar mashin Pp masana'anta iska.

3.Fim ɗin mai rufi na PP

An shigar da masana'anta na PP ɗin da cokali mai yatsa a kan injin fim ɗin, PP masana'anta an rufe shi da kauri na filastik 30 don ƙara ƙimar danshi-tabbatar. Mirgine na pp masana'anta mai rufi da birgima.

4.Bugu a kan jakunkuna na PP

Haƙiƙa fim ɗin da ya fi ƙwararrun ƙwararru da kyakkyawan jakar Fasaha, Fasaha ta Fasaha

5.An gama samfurin samfurin da shirya

Wadanda ba a buga ba ko buga PP da aka buga ko Flexo PP Suffuka: An gama sakin Rolls PP ta hanyar tsarin ninkaya (idan akwai), kuma an yanke samfurin. Sai ka fara farko, bugawa daga baya, ko dinka daga baya, buga farko. Abubuwan da aka gama sun tafi ta atomatik kirga mai isar da kayan aiki da kayan abinci.

Jaka da aka saka a cikin akwatunan PP tare da Motocin buga fim a cikin Rolls ta hanyar tsarin atomatik, m latsa, yankan sanduna, da shirya.

A cikin takaice, polypropyleren polymer shine kayan zabi a lokacin da aka tsara masana'antar masana'antar da aka tsara filastik lokacin da ya zo ga samar da kayan kwalliya don ciminti. Adana, sufuri, da kulawa da sumunti duk abin da zai amfana daga jiki, sunadarai, da kaddarorin na kayan aikin polypropylene.

CEWA KYAUTATA KUDI:

| Fasali: | |

| M | Bugawa mai launi (har zuwa launuka 8) |

| Nisa | 30cm zuwa 60cm |

| Tsawo | 47cm zuwa 91cm |

| Therno | 80cm zuwa 180cm |

| Tashin hankali | 9cms zuwa 22cms |

| Yarabawa Saa | 8 × 8, 10 × 10, 12 × 12 |

| Yawan kauri | 55GSM zuwa 95GSM |

Jaka da aka saka galibi suna magana: jakunkunan filastik an yi su ne da polypropylene (PP a Turanci) kamar yadda babban albarkatun ƙasa, sannan aka fitar da shi cikin farji.

1. Masana'antu da kayan aikin kayan aikin gona

2. Jaka mai ɗaukar abinci