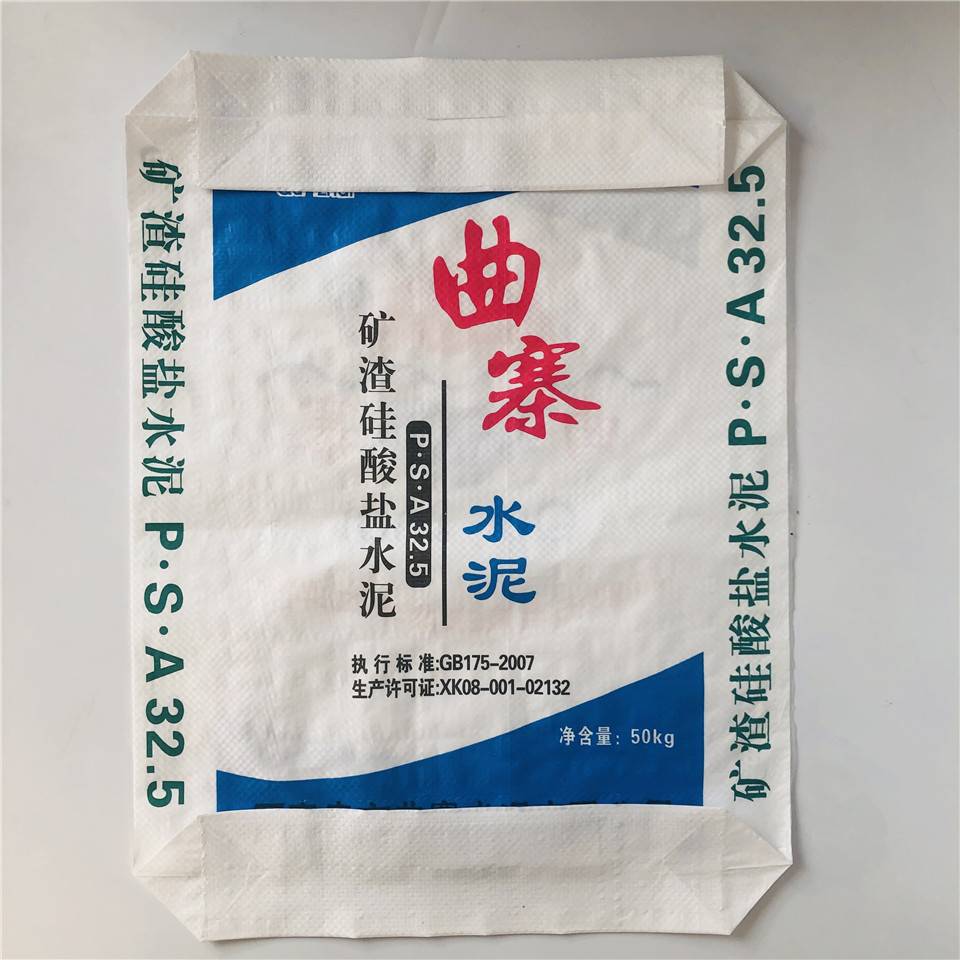

Valve Polypropylene Woven Sack

Basic Info.

- Promotional Shopping Bags

- -Grain & Pulses Bags

- -Seed Bags

- -Fertilizer & Chemical Bags

- -Sugar Bags

- -Food & Spices Bags

- -Animal Feed Bags

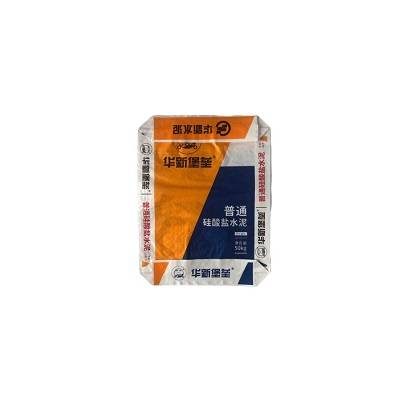

- -Building materials

- -putty ,concrete,cement

| Features: | |

| Multi | color printing (Up to 8 colors) |

| Width | 30cm to 60cm |

| Length | 47cm to 91cm |

| bottom width | 80cm to 180cm |

| Valve length | 9cms to 22cms |

| Fabric weave | 8×8, 10×10, 12×12 |

| Fabric thickness | 55gsm to 95gsm |

Company Profile

Our main products are PP woven bags, Bopp laminated bags, Ad*Star block bottom bags, and big bags/Jumbo bags etc., all of them are highly sophisticated products.

“Customer first and reputation first” is the vision we always adhere to.

EAR 2001 The first factory located in Shijiazhuang, the capital city of Hebei Province.

Occupies over 30,000 square meters. Over 300employees.

YEAR 2011 The second factory named Shengshijintang Packaging Co., Ltd.

Occupies over 45,000 square meters. About 300 employees.

YEAR 2017 The third factory also a new branch of Shengshijintang Packaging Co., Ltd.

Occcupies over 85,000 square meters. About 300 employees.

OUR EQUIPMENT

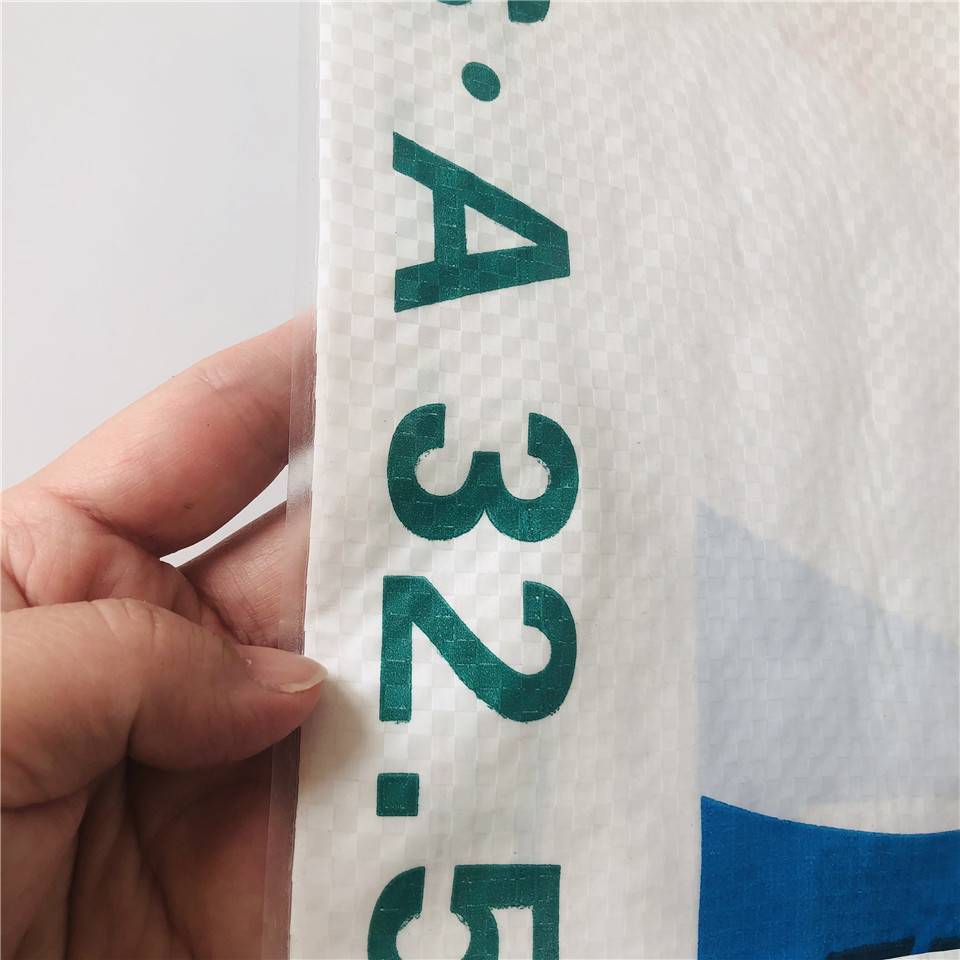

As the first company in China to improt the bottomer ad*starKON in 2009, we gathered rich experience in bag making and a deep understanding of differentiated bags in specific industries. Top equipment, 100% virgin Polypropylene material, more than 30,000 metric tons annual throughput. That provides a reliable guarantee for the subsequent production of high-quality packaging bags.

About Block Bottom Bags

AD* Star is the well-known bag concept for powdery material – in use worldwide, patented internationally, and produced exclusively on Starlinger machines. The brick-shaped PP woven bags, produced without adhesives by heat-welding of the coating on the fabrics, were developed with automated filling and landing processes in mind. As a result of the material characteristics and the special production process, the weight of an average 50kg block bottom cement sack can be as low as 75 grams. A comparable 3-layer paper bag will weigh about 180 grams and a PE-Film bag 150 grams. The economical use of raw materials not only helps minimize cost, it is also a valuable contribution to the preservation of our environment.

Factory workshop show

Our Advantages

1. Factory produce factory export.

2. Engaged in this industry since 2001, with more than 20 years of experience

3. Top-grade equipment has been introduced since 2009 to ensure higher quality and reduce the overall cost for customers.

4. Occupied a total of 160,000m2 of production area and can make sure an annual output of more than 500 Million bags.

5. Professional design team, well-cooperated cylinder workshop, with the sufficient experience in handling more than 6,000 kinds of bags, to meet the unique needs of customers

6. Good reputation, we aim at a long and stable relationship with our valuable customers.

7. Professional Services

*pre-sale service

Any of your questions will be taken seriously and offer you reference opinions.

* In-sale service

Make you posted on the production progress with on-site follow-up for each production step.

* After-sales service

We are responsible for EACH bag we produced. Feel free to contact us in case any questions you may have. We will answer you timely, and cooperate with you positively.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags