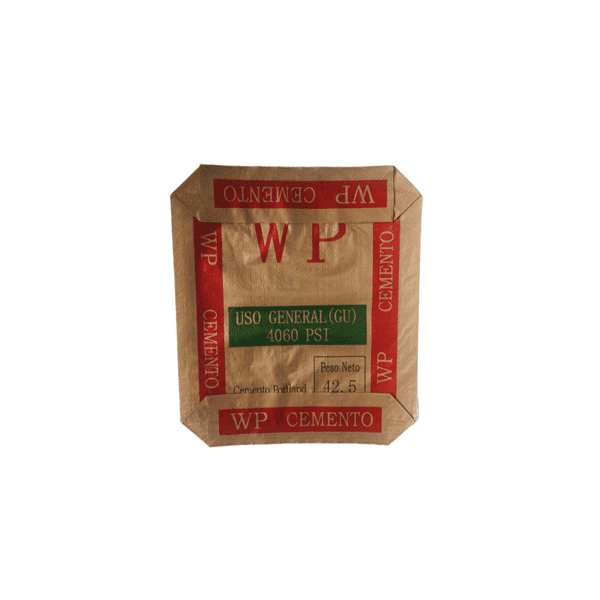

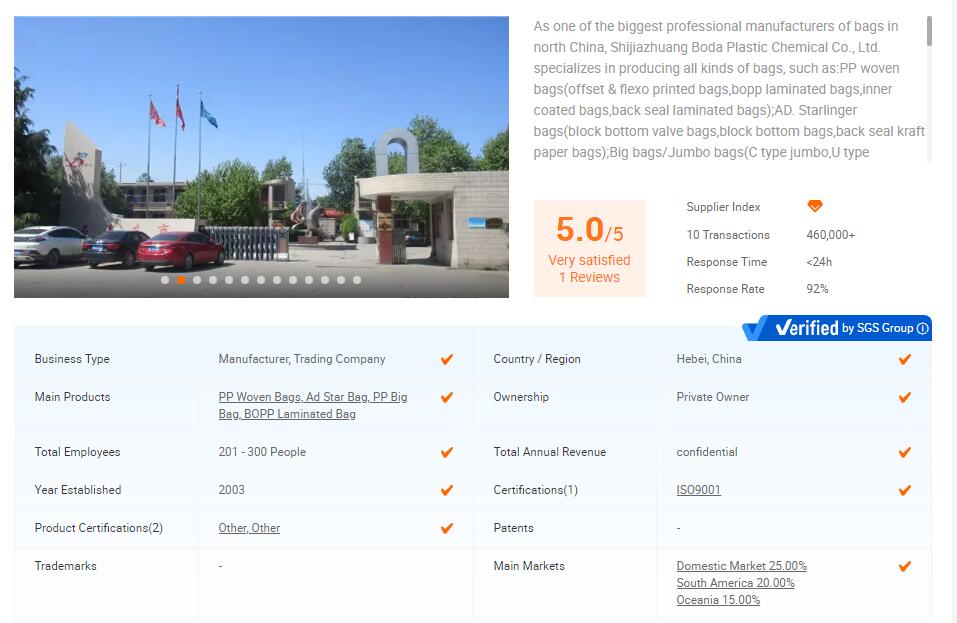

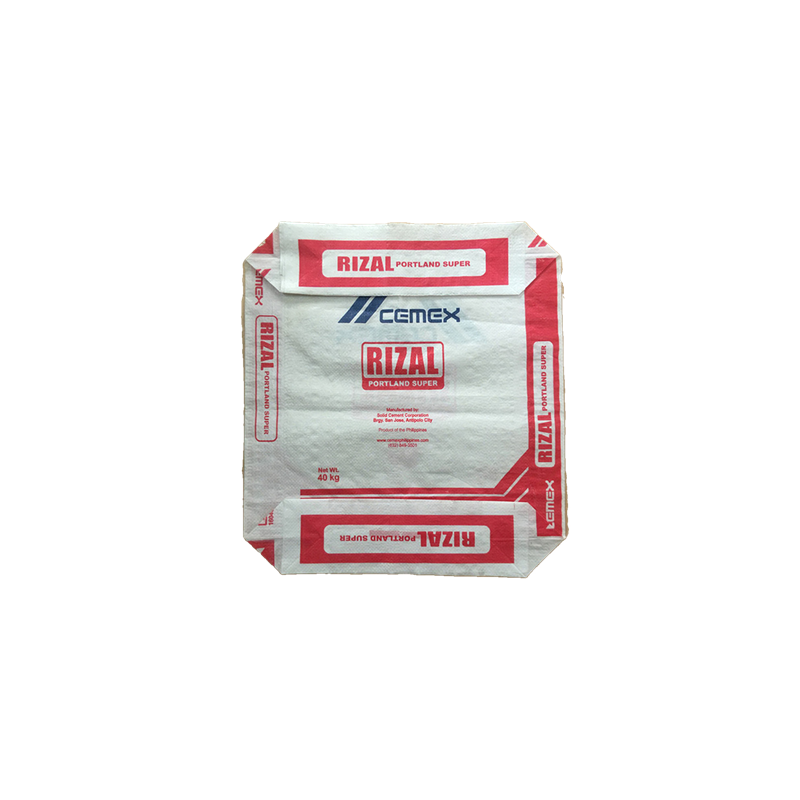

Brown 50kg cement valve bag

moisture-proof. With the continuous deepening of the industrial automation process of cement or flour enterprises, and the further emphasis on the quality of cement flour packaging bags, the quality and performance requirements for all-plastic square bottom valve mouth woven bags are getting higher and higher, which are mainly reflected in: mechanical properties. , which is strong, resistant to falling and beating, and can handle long-distance transportation. If it has good moisture-proof and sealing properties, it can ensure that the product will not get damp during storage and transportation, and the product will not leak and will not cause product loss. In terms of automation function, filling can be performed efficiently, quickly and accurately.

|

Name

|

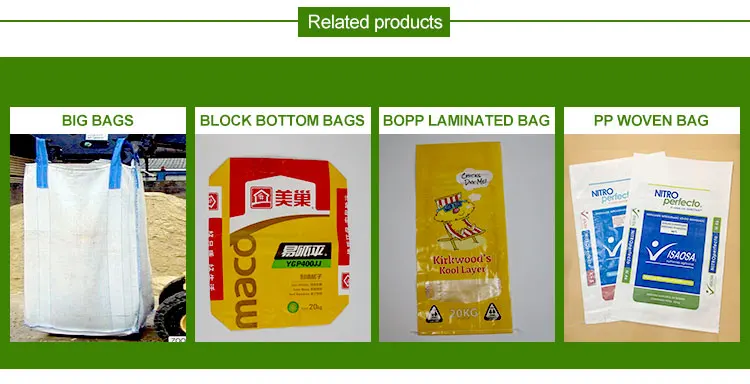

pp woven bag

|

|

Length

|

As you requirements

|

|

Width

|

30-70cm

|

|

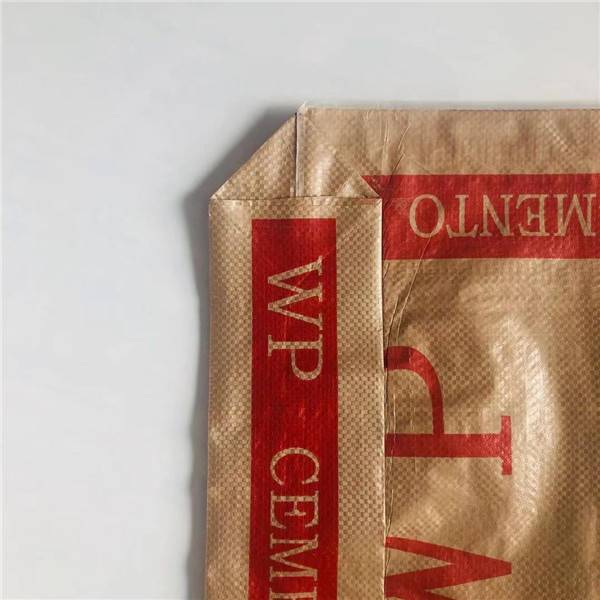

Structure

|

PP+PE+BOPP

|

|

Fabric thickness

|

55-85g/m2

|

|

Top

|

open mouth;valve top

|

|

Bottom

|

Block bottom/Square bottom

|

|

Side

|

With or without “M” gusseted

|

|

PE liner

|

With or without PE liner

|

|

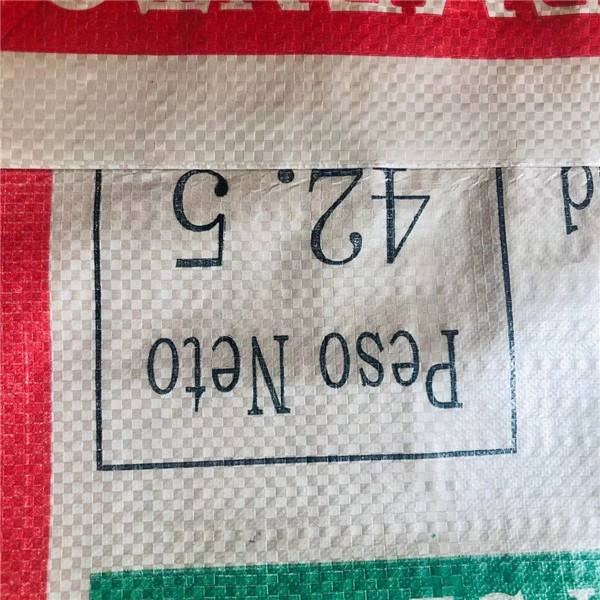

Loading weight

|

20kg, 25kg 50kg, or as your requirements

|

|

General size

|

52*65*10cm; 50*61*11cm; 50*64*13cm ……

|

|

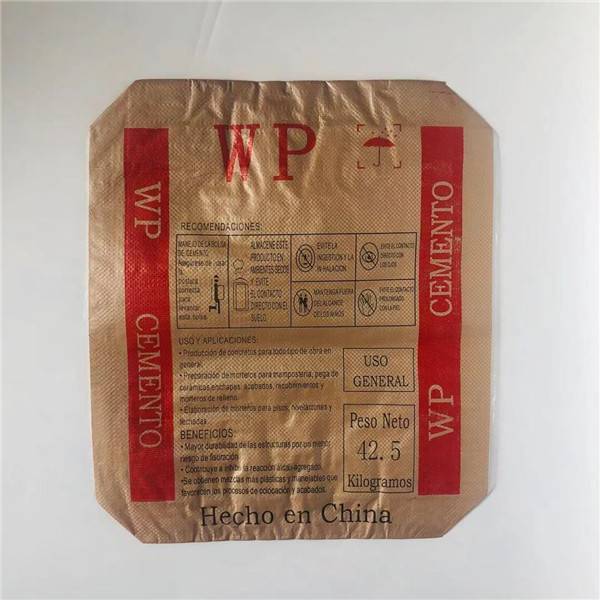

Printing

|

Offset printing ; flexo printing ; gravure printing;BOPP printing

|

|

MOQ

|

5,000PCS

|

|

Package

|

110,000PCS/PER 20’GP; 270,000PCS/40’HQ with pallet

|

How to get sample?

1. Existing Samples: free

2. Custom Samples :according to the specification, sample time: 3-5 days

1. please complete your design or confirm our design firstly

2. we use eco-friendly printing ink.

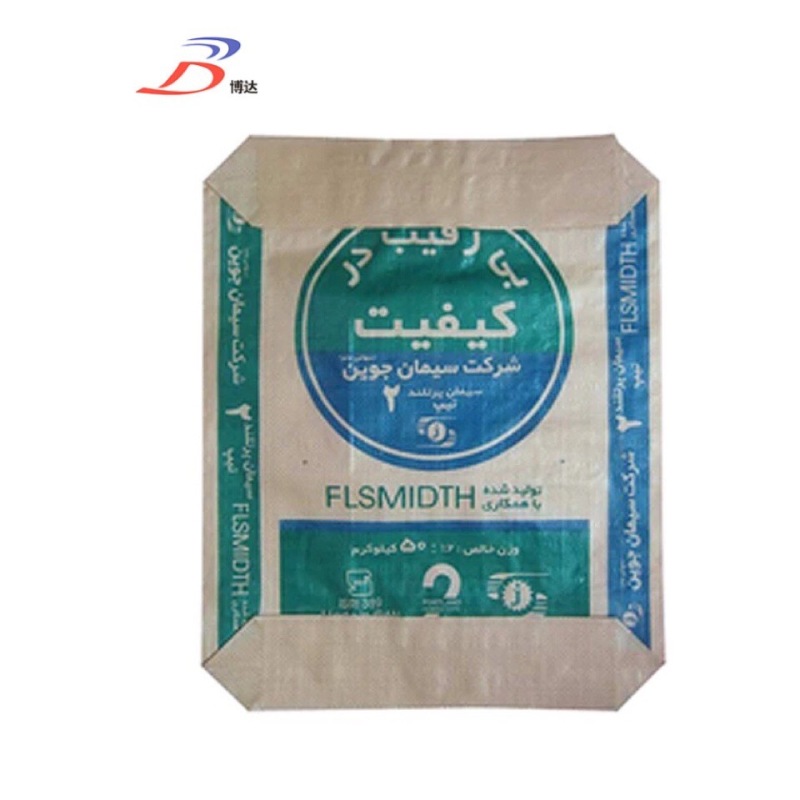

At present, all-plastic square bottom valve bags are widely used in cement companies and flour companies at home and abroad.They are characterized by fast filling, clean and beautiful appearance, good sealing, exquisite printing, large packaging volume, and can be packaged in a standing position. Suitable for stacking and transportation operations. Cooperating with the automatic filling of packaging machinery, the valve port on the top can achieve automatic sealing after it is filled with cement or flour,saving time and effort. The all-plastic square bottom valve bag is produced by a special square bottom valve bag making machine.

It adopts heat-sealing production and uses a coated PP woven bag tube. The heat-sealing production process is used to produce a low-cost square bottom valve bag suitable for automatic packaging. The upper and lower sealing of this square bottom valve bag does not require any sewing. Instead of using threads, a covering layer of woven fabric is used for stable heat sealing. The film on the bottom of the bag, as well as the film on the valve flap and back sealing sheet, are softened by hot air and then heat-sealed together through pressure.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags