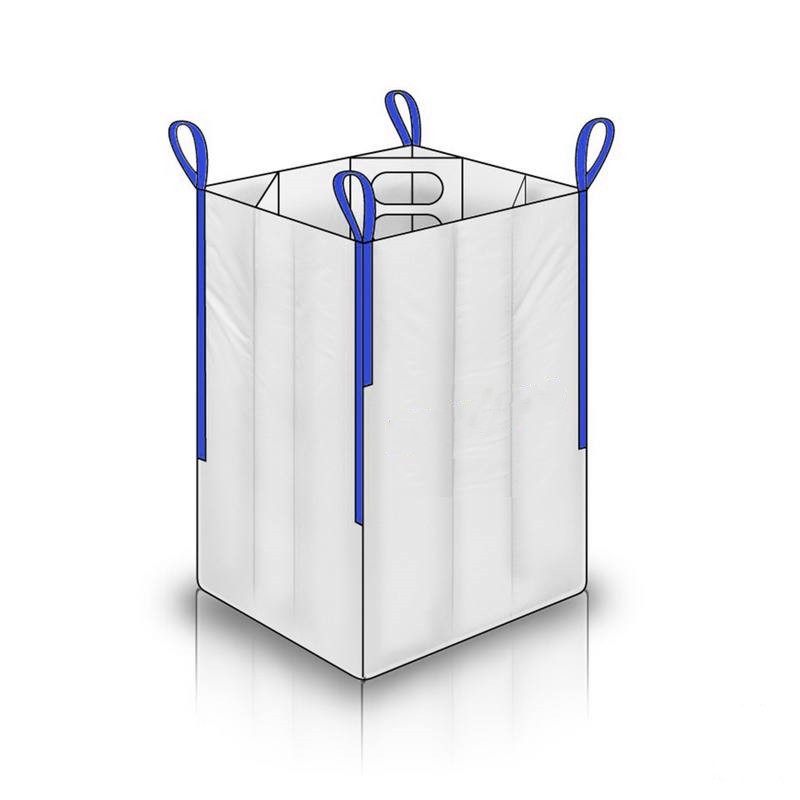

Baffle bags are manufactured with sewing inner baffles across the corners of the four panels of the FIBCs to prevent distortion or Swelling and to ensure the square or the rectangular shape of the bulk bag during transportation or storage. These baffles are manufactured accurately to allow the material to flow into the corners of the bag resulting in less storage space occupied and decreased transportation costs up to 30% in comparison with a standard PP Big Bag.

A baffle or Q-type FIBCs can be coated or uncoated and comes with an optional PE liner inside. High Quality Baffle Big Bag gives better stability and improved loading efficiency of containers and trucks.

1000kg New Material PP Baffle Big Bag benefits :

- Allows 30% more material to be filled per bag as compared to the standard FIBC material flows uniformly to all four corners of the bag.

- Reduced leakages and spillage.

- Efficient and optimum utilization of the storage space available.

- Improved stacking in the warehouse makes it look neater and improves overall aesthetical appeal.

- Remains firm in the pallet dimensions when filled.

The options of our PP Baffle Plastic Bulk Bag :

- Safe Working Load (SWL): 500 kg to 2000 kg.

- Safety Factor Ratio (SFR) : 5:1, 6:1

- Fabric : Coated / Uncoated.

- Liner: Tubular / Shaped.

- Printing: Up to 4 Colour Printing on 1/2/4 sides.

- Various Top and Bottom construction options.

Post time: Sep-21-2022