How are AD*STAR Woven Poly Bags Manufactured?

Starlinger Company supplies integrated bag converting machinery to produce the woven valve bag from start to finish. Production steps include:

Tape Extrusion: High-strength tapes are produced by stretching after the resin extruding process.

Weaving: Tapes are woven into tear-proof fabric in circular looms.

Coating: A thin layer of PP film is laminated to the woven fabric.

Printing: Up to 7 colors, including photorealistic quality graphics can be printed on the bag fabric

Slitting: Top, bottom, and valve patches are pre-cut for the converting line.

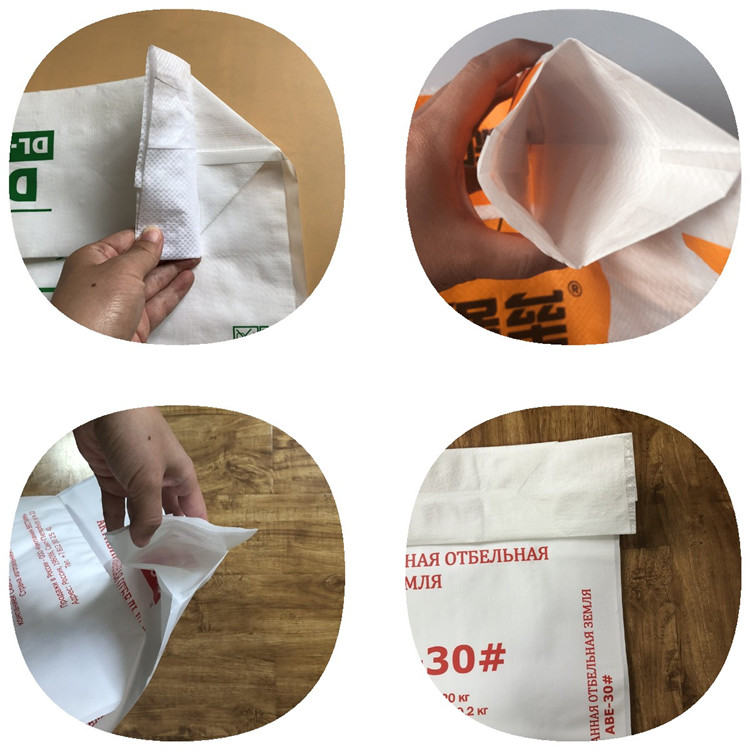

Converting: Using Starlinger machines, sacks are assembled by forming the block bottom and applying patches and the valve using hot air sealing technology. No glue is used to seal the bag.

Baling: Bags are palletized and baled. around 5,000-7,000 bags can be baled in a single pallet.

AD*STAR® Bag Specifications and Sizes

Specifications

| Type: | Block Bottom Valve |

| Material: | Coated Woven PP Tapes |

| Construction: | PP woven fabric + Pe coated |

| Tape Width: | 2.5mm – 5mm |

| Fabric Weight | 50 – 80 gsm |

| Coating Weight: | 17 – 25 gsm |

| Valve Material: | Woven PP, PE Film, Non-Woven Spunbond |

| Perforation: | Adjustable Levels of Perforation |

| Valve Type: | Standard Internal, Tuck-in, and Sonic Seal |

What can AD*Star® Block Bottom Woven Valve Sacks/bags be used for?

pp woven valve bags can be used for all types of free-flowing goods such as :

Cement

Building materials

Fertilizer

Chemicals

PVC Resin

Masterbatch

Seeds

Mortar

Gypsum

Lime

Flour

Sugar

Animal feed

Ready mix

PP Resin

PE Resin

Corn

Sand

Post time: Nov-22-2022