Great news for industrial fibc bags company!

Our company can customize woven bags depending on customer requirements with a factory that is in full compliance with the production standards for food grade woven bags and UN certified woven bags for hazardous materials transportation. jintang(boda) possesses two sets of Austrian imported fully automatic Starlinger winding machines and 300 sets of circular looms, ensuring the production efficiency and quality of woven bags, as well as reducing the production cost.

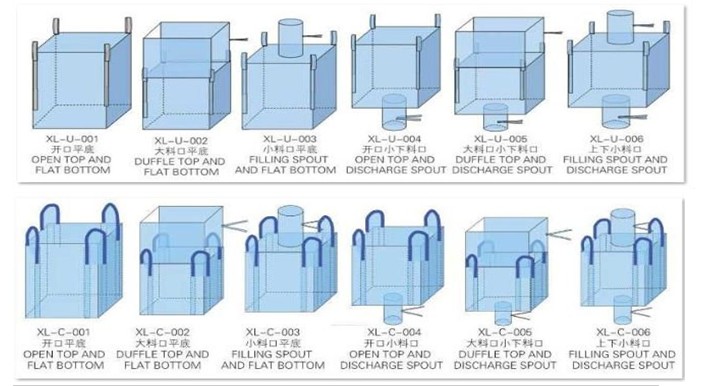

The top of the duffle bag is designed to provide easy access to the interior of the bulk bag, making loading and unloading materials simple. This will save workers valuable time and energy and reduce the risk of leaks or accidents during loading and unloading.

The discharge spout feature is another valuable addition to fibc container bag. This feature enables controlled and precise material unloading, reducing the risk of waste and increasing overall processing efficiency. This is particularly beneficial for companies working with fine powders or materials that require careful handling during unloading.

These new features, combined with the customizable specifications of the FIBC, will provide industrial companies with multiple options to customize the FIBC to their specific needs. Regardless of the size, shape or material of the bag, companies can now also choose to include duffle bag top and vent features as part of their custom specifications.

This news is sure to be welcomed by companies that rely on bulk bags for their shipping and storage needs. By fibc bag design to meet their specific requirements, companies can increase efficiency, reduce waste and improve safety when handling bulk materials.

Overall, the addition of baggage tops and discharge openings to FIBCs represents a significant advance for industrial companies in the transportation and handling of bulk materials. With these new capabilities, companies can expect greater flexibility and efficiency in their operations.

Post time: Feb-27-2024