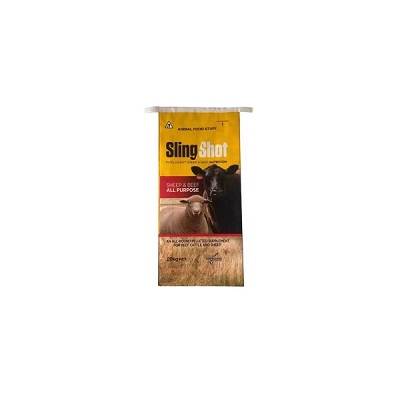

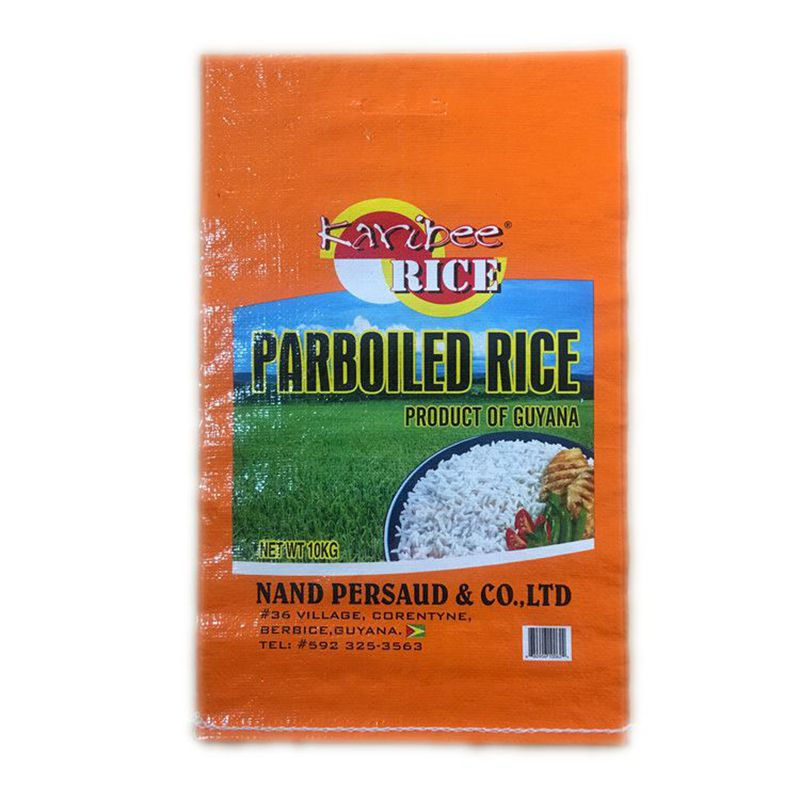

pp bopp laminated bag

Our BOPP laminated bags are made with advanced OPP lamination technology, ensuring a strong protective layer, thus extending the life of your product. OPP laminate film not only provides a barrier against moisture and dust, but also adds gloss and improves the visual appeal of the packaging.One of the outstanding features of our BOPP laminated bags is their lightweight yet strong construction. This makes them easy to handle and transport while still providing the necessary protection for your products. These bags are available in a variety of sizes and designs, allowing you to choose the bag that best suits your specific needs. Additionally, customizable options allow you to display your brand logo and colors to make your products stand out on the shelf.

| Product Type | PP woven bag, with PE liner, with lamination, with drawstring or with M gusset |

| Material | 100% new virgin polypropylene material |

| Fabric GSM | 60g /m2 to 160g /m2 as your requirements |

| Prinitng | One side or both sides in multi-colors |

| Top | Heat cut / cold cut, hemmed or not |

| Bottom | Double / single fold ,double stitched |

| Usage | Packing rice,fertilizer,sand, food,grains corn beans flour feed seed sugar etc. |

China leading supplier and manufacturer of PP woven packaging and storage sack bags

YEAR 2011 The second factory named Shengshijintang Packaging Co., Ltd.

Occupies over 45,000 square meters. About 300 employees.

YEAR 2017 The third factory also a new branch of Shengshijintang Packaging Co., Ltd.

Occupies over 85,000 square meters.

For automatic filing machines , the bags must keep To be smooth and unfolded , so We have the following packing term , please check according To your filling machines .

1. Bales packing : free of charge , workable for semi-automatization filing machines , workers hands are needed when packing .

2. Wooden pallet : 25$/set, common packing term , convenient To loading by forklift and could keep the bags flat , workable forcompleted automatic filing machines To large production ,

but loading few than bales , so higher transportation cost than bales packing .

3. Cases : 40$/set, workable for packages , which has highest requirement for flat , packing the least quantity in all packing terms , with the highest cost in transportation .

4. double planks: workable for railway transportation , could add more bags , reducing empty space , but it is dangerous for workers when loading and unloading by forklift , please consider second .

Our advantage

2. Good Service: “Customer first and reputation first” is the tenet we always adhere to .

3. Good Quality: strict quality control system, piece-by-piece inspection.

4. Competitive Price: low profit, seeking long-term cooperation.

Our Service

2. We can make a design according to your requirements.

3. We promise to reply to your inquiry about product and price within 24 hours.

4. We can provide samples before mass production.

5. Good after-sale service offered.

6. We can ensure to make our business relationship confidential to any third party.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags