Quality Inspection for Bulk Bag 500kg - FDA approved PP woven Super sack – Jintang

Quality Inspection for Bulk Bag 500kg - FDA approved PP woven Super sack – Jintang Detail:

Model No.:Boda-fibc

Application:Chemical

Feature:Moisture Proof, Antistatic

Material:PP, 100% Virgin PP

Shape:Plastic Bags

Making Process:Plastic Packaging Bags

Raw Materials:Polypropylene Plastic Bag

Bag Variety:Your Bag

Size:Customized

Color:White Or Customized

FABRIC WEIGHT:80-260g/m2

Coating:Workable

Liner:Workable

Print:Offset Or Flexo

Document Pouch:Workable

Loop:Full Stitching

Free Sample:Workable

Additional Info

Packaging:50pcs per bale or 200pcs per pallet

Productivity:100,000pcs per month

Brand:Boda

Transportation:Ocean,Land,Air

Place of Origin:China

Supply Ability:on time delivery

Certificate:ISO9001, SGS, FDA, RoHS

HS Code:6305330090

Port:Xingang,Qingdao,Shanghai

Product Description

Boda is one of China’s top packaging producers of specialty Polypropylene Woven Bags. With world-leading quality as our benchmark, our 100% virgin raw material, top-grade equipment, advanced management, and dedicated team allow us to supply superior bags all over the world.

Our main products are: Pp Woven Bags, BOPP Laminated Woven Sacks, BOPP Back Seam Bags, Block Bottom Valve Bags, Pp Jumbo Bags, Pp Woven Fabric

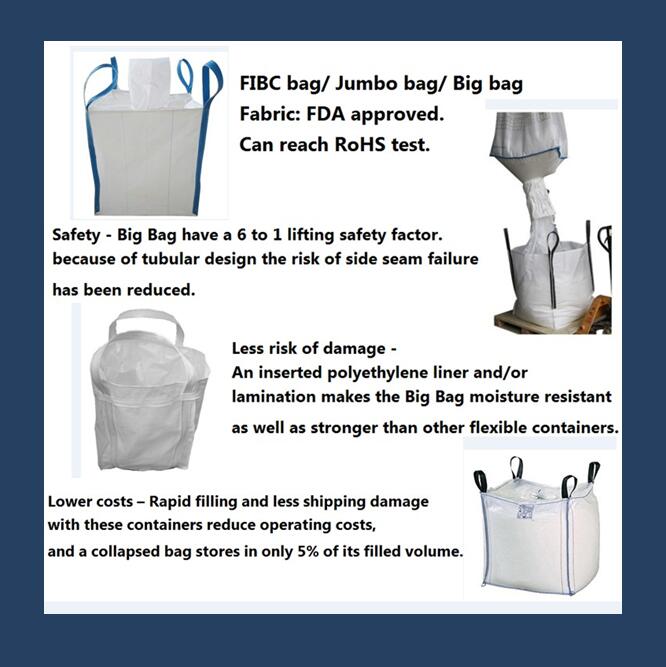

PP Big Bag / jumbo bag/ Super Sack/ FIBC Sack

Your options:

1. standard FIBC: U panel/ circular/ coated/ uncoated/ lined

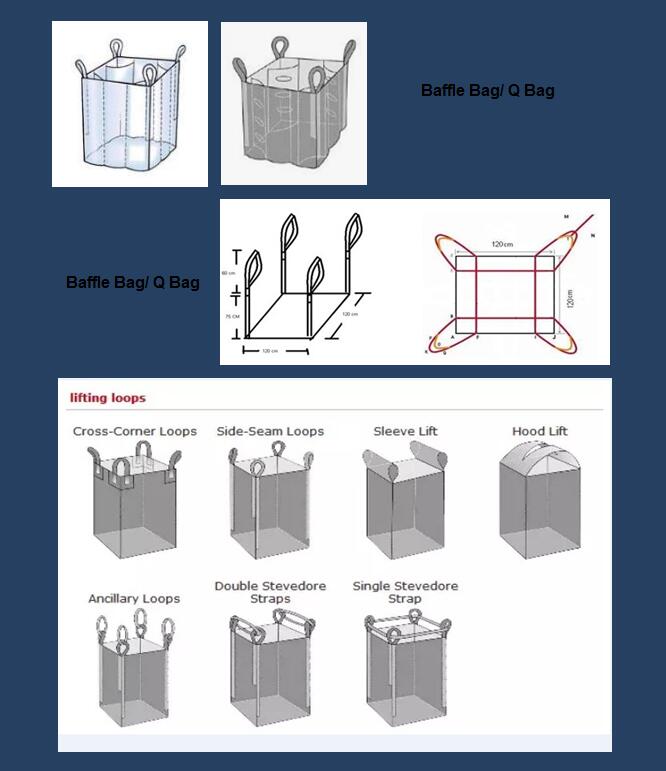

2. Baffled FIBC: also called PP Q bag, such bags can prevent bulging deformation after loaded and beneficial for transportation.

3. sling bag: bearing mainly rely on the belt. Bags normally for transporting purpose.

4. Sift-proof FIBC: they are sewn with leak-proof materials, mainly used for powdered products, preventing leakage from the seam.

5. Vented FIBC: radial weaving less than normal density so that they have characters of ventilation of humidity and prevent mildew of goods.

6. Food Grade FIBC: these bags meet the requirements of packaging food products. FDA approved.

7. Danger-goods packaging FIBC: we obtain licenses for packaging dangerous goods.

8. Anti-static FIBC: avoid the deanger of dust accumulation or explode caused by static discharge.

9. Anti-UV FIBC: bag with long lifetime, anti-aging

Specification:

Material: 100% new PP

PP Fabric weight: from 80-260g/m2

Dimension: regular size; 85*85*90cm/ 90*90*100cm/ 95*95*110cm or customized

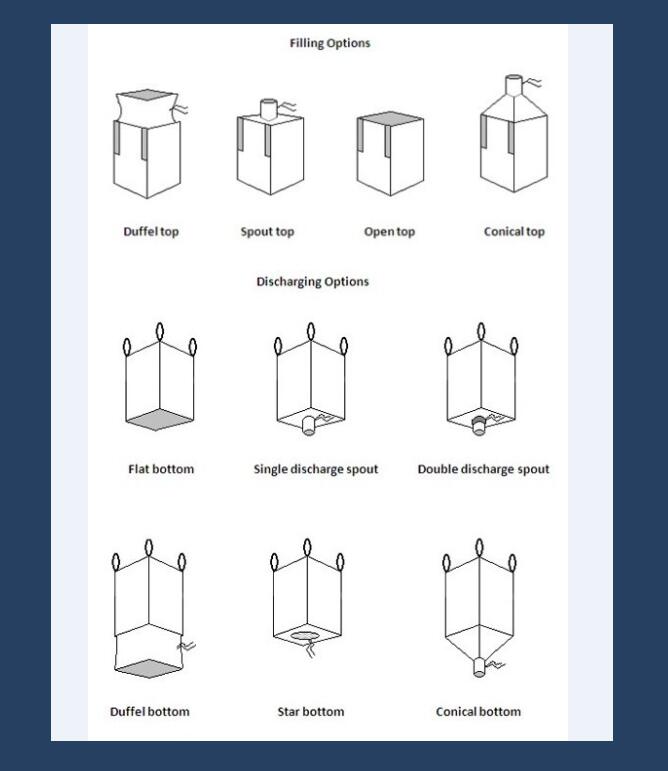

Top Option ‹Filling›: Top Fill Spout/Top Full Open/Top Fill Skirt/Top Conical or customizedBottom Option ‹Discharge›: Flat Bottom/Flat Bottom/With Spout/Conical Bottom or customized

Loops: 2 or 4 belts, cross corner loop/Double stevedore loop/side-seam loop or customized

Color: white, beige, black, yellow or customized

Printing: Simple offset or flexible printing

Document pouch/label: workable

Surface dealing: Anti-slip or plain

Sewing: Plain/ Chain lock with optional soft-proof or leakage proof

Liner: PE Liner hot seal or sewing on the edge of bottom and top high transparent

Packaging details: about 200pcs per lallet or under customers’ requirements

50pcs/bale, 200pcs/pallet, 20 pallets/20′ container, 40pallets/40′ container

Application: Transport packaging/ Chemical, Food, Construction

Our workshop

Looking for ideal Circular PP Woven Jumbo Bag Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the U Panel Super Sack are quality guaranteed. We are China Origin Factory of Plastic Resin PP Big Bag. If you have any question, please feel free to contact us.

Product Categories : Big Bag / Jumbo Bag > FIBC Bag

Product detail pictures:

Related Product Guide:

Troubleshooting during the production of woven bags

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Quality Inspection for Bulk Bag 500kg - FDA approved PP woven Super sack – Jintang , The product will supply to all over the world, such as: Botswana, Manchester, venezuela, We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.