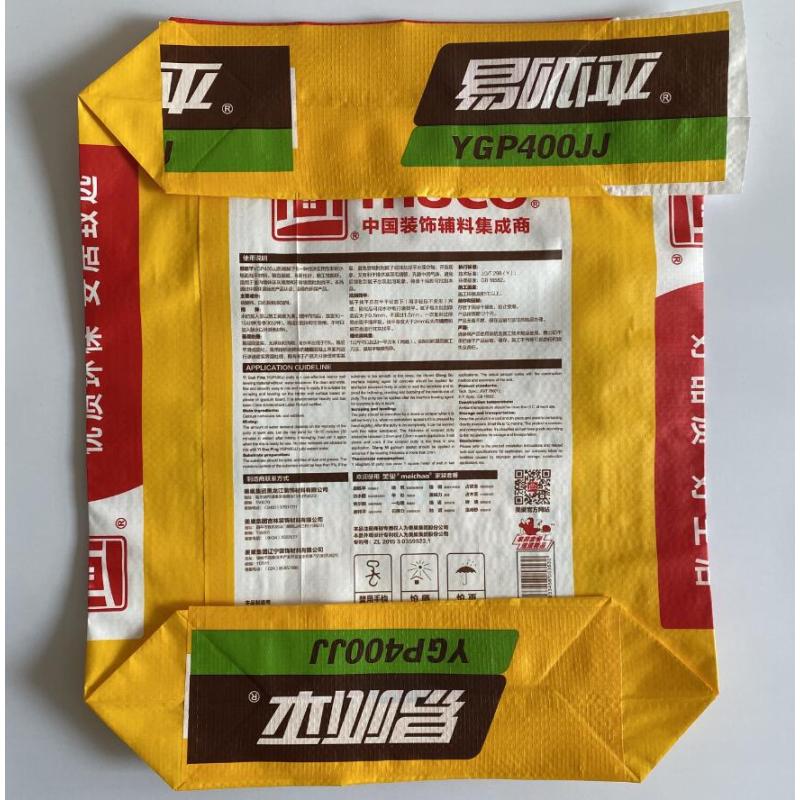

20kg Block Bottom PP Woven Putty Bag with valve

Model No.:Boda- ad

Woven Fabric:100% Virgin PP

Laminating:PE

Bopp Film:Glossy Or Matte

Print:Gravure Print

Gusset:Available

Top:Easy Open

Bottom:Stitched

Surface Treatment:Anti-slip

UV Stabilization:Available

Handle:Available

Application:Food, Chemical

Feature:Moisture Proof, Recyclable

Material:PP

Shape:Square Bottom Bag

Making Process:Composite Packaging Bag

Raw Materials:Polypropylene Plastic Bag

Bag Variety:Back Seal Bags

Additional Info

Packaging:Bale/ Pallet/ Export carton

Productivity:3000,000pcs per month

Brand:Boda

Transportation:Ocean,Land,Air

Place of Origin:China

Supply Ability:on time delivery

Certificate:ISO9001, SGS, FDA, RoHS

HS Code:6305330090

Port:Tianjin,Qingdao,Shanghai

Product Description

BOPP Laminated with Gravure Print Block Bottom Valve PP Putty bag

This PP woven sack is where the interaction of strength and elongation of woven PP fabrics comes in: Starlinger tapes show a high elongation that is retained over the entire process chain. In combination with the high strength of the tapes, this results in a higher TEA(Tensile Energy Absorption) than comparable products and thus in an optimal performance under stress.

How to produce a Block Bottom Valve Bag by AD* STARKON machine

Extruding PP thread/tape

Weaving pp tapes to tubular fabric

Coating or Laminating

Printing the body

Ad*Star Machine plays its roll

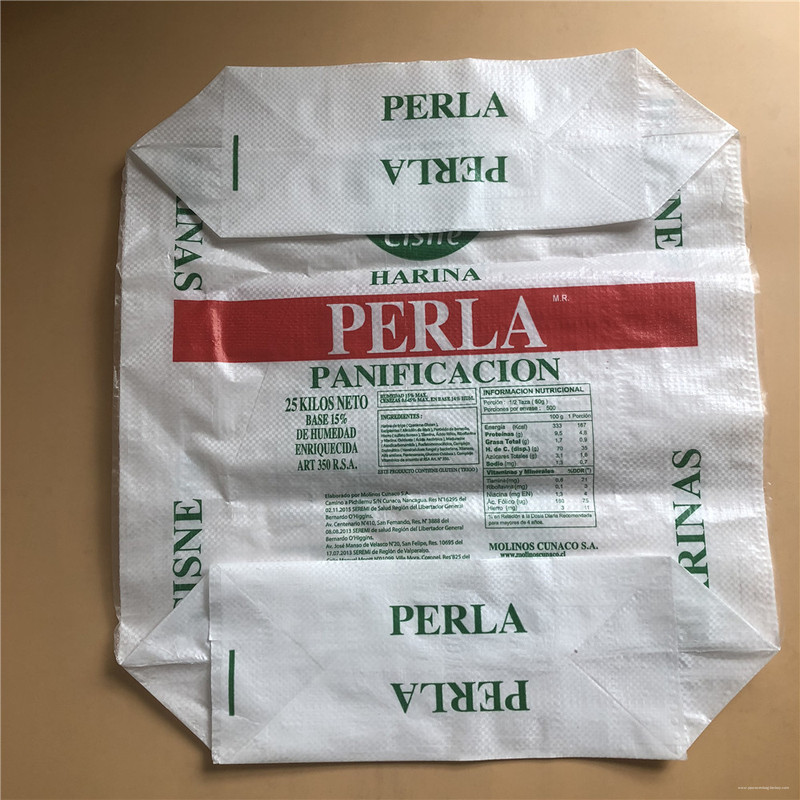

Valve bags with block bottom or flat bottom also called paste bottom bags, is the most popular packing bag in the world now. Through automatic filling equipment, the goods come into the bag from the valve at the top or the bottom, become brick shape after filled. Block Bottom Valve Bags can be made of pp woven, pp woven compound with craft paper/ PE.

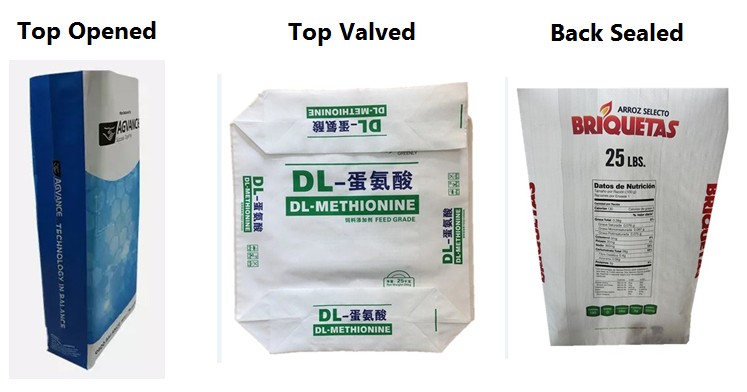

The Ad*Star Sack can be produced either as a one-layer Block bottom valve bag (V-BB) or as an open mouth bag with a block bottom without valve (OM-BB) and with or without micro-perforations.

Fabric Construction – Circular Pp Woven Fabric (no seams) or Flat PP Woven Fabric (back seam bags) Laminate Construction – PE coating or BOPP Film Fabric Colors – White, Clear, Beige, Blue, Green, Red, Yellow or customized Printing – Off-set print, Flexo print, gravure print. UV Stabilization – Available Packing – 5,000 Bags per Pallet Standard Features – No stitching, completely hot welding

Optional Features:

Printing Anti-slip Embossing Micropore

Valve extendable Kraft paper combinable Top opened or valved

Sizes Range:

Width: 350mm to 600mm

Length: 410mm to 910mm

Block width: 80-180mm

Weave: 6×6, 8×8, 10×10, 12×12, 14×14

Our company

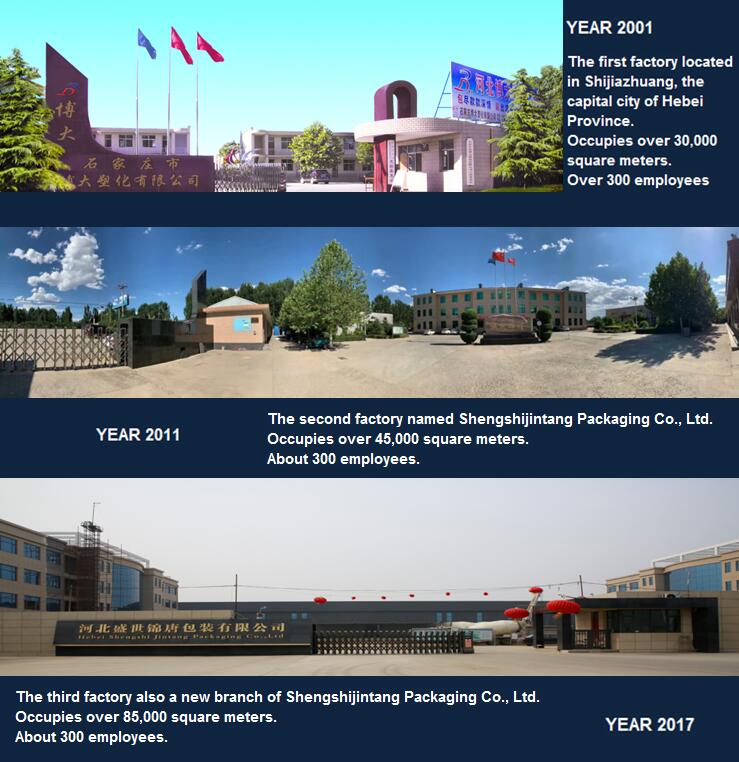

Boda is one of China’s top packaging producers of specialty Polypropylene Woven Bags. With world-leading quality as our benchmark, our 100% virgin raw material, top-grade equipment, advanced management, and dedicated team allow us to supply superior bags all over the world.

Our company covers an area totally of 160,000 square meters and there are more than 900 employees. We possess a series of advanced Starlinger equipment including extruding, weaving, coating, laminating and bag produce. What’s more, we are the first manufacturer in domestic that imports the AD* STAR equipment in the year 2009 for Block Bottom Valve Bag Production.

Certification: ISO9001, SGS, FDA, RoHS

Looking for ideal PP Valve Putty Bag Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Block Bottom Putty PP Sack are quality guaranteed. We are China Origin Factory of PP Woven Construction Material Bag. If you have any question, please feel free to contact us.

Product Categories : Block Bottom Valve Bag > PP Woven Putty Bag

Woven bags are mainly speaking: plastic woven bags are made of polypropylene (PP in English) as the main raw material, which is extruded and stretched into flat yarn, and then woven, woven, and bag-made.

1. Industrial and agricultural product packaging bags

2. Food packaging bags